Metal welding is a necessary and critical process of metal fabrication in various industries, but defects can compromise the integrity of the weld.

Understanding these defects is essential for quality control.

Here, we’ll delve into each defect, explore its causes and effects, and discuss troubleshooting solutions.

1. Porosity

Porosity refers to the presence of small holes or voids (pores) in a welded joint or the heat-affected zone, leading to weakened weld integrity.

Causes: Common causes include contaminants such as moisture, oil, or grease on the base material. Inadequate shielding gas, incorrect welding technique, and environmental factors, like drafts, can also contribute to porosity. Gas entrapment may occur during the solidification process if the weld pool is too turbulent or if the arc is unstable.

Troubleshooting: To mitigate porosity, ensure thorough cleaning of the workpiece before welding. Use appropriate shielding gases and adjust welding parameters, including voltage and travel speed, to maintain arc stability. Regularly inspect for contaminants and employ effective pre-weld preparation.

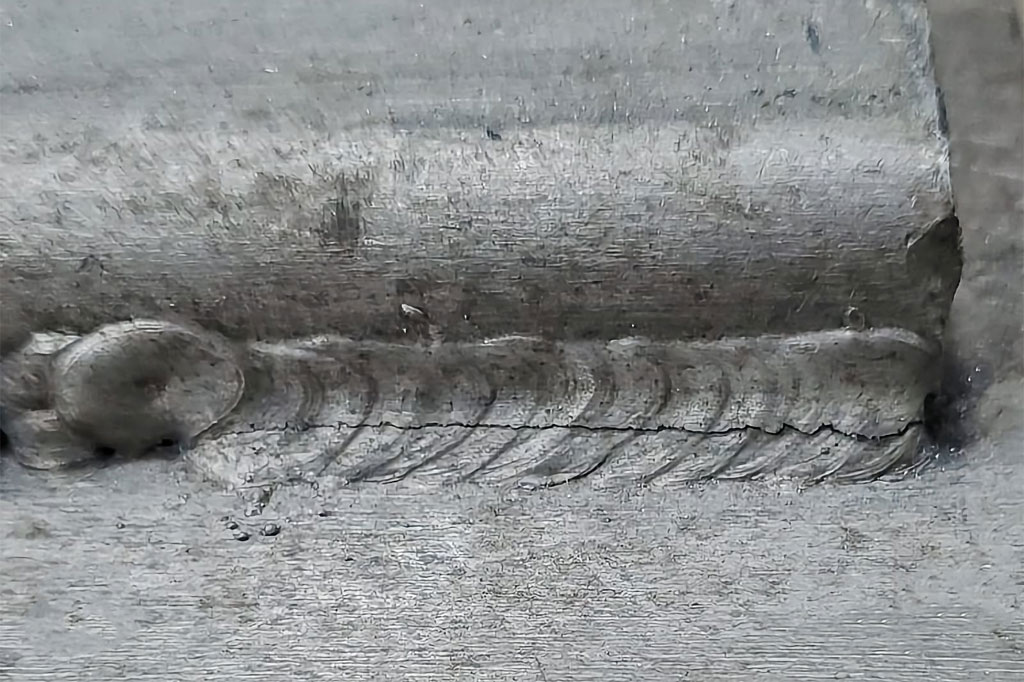

2. Cracking

Cracking manifests as fractures in the weld metal or the heat-affected zone (HAZ), leading to significant structural weaknesses.

Causes: Cracking can occur due to several factors, including rapid cooling, which can lead to thermal stresses that exceed the material’s yield strength. High carbon content in the material may increase hardness and brittleness, while insufficient preheating can exacerbate stress concentrations. Additionally, hydrogen embrittlement—often due to moisture contamination—can lead to delayed cracking after the weld has cooled.

Troubleshooting: To mitigate cracking, preheat materials appropriately based on their composition and thickness. Control the cooling rate by using insulated blankets or controlled environments, and select low-hydrogen electrodes to minimize hydrogen uptake.

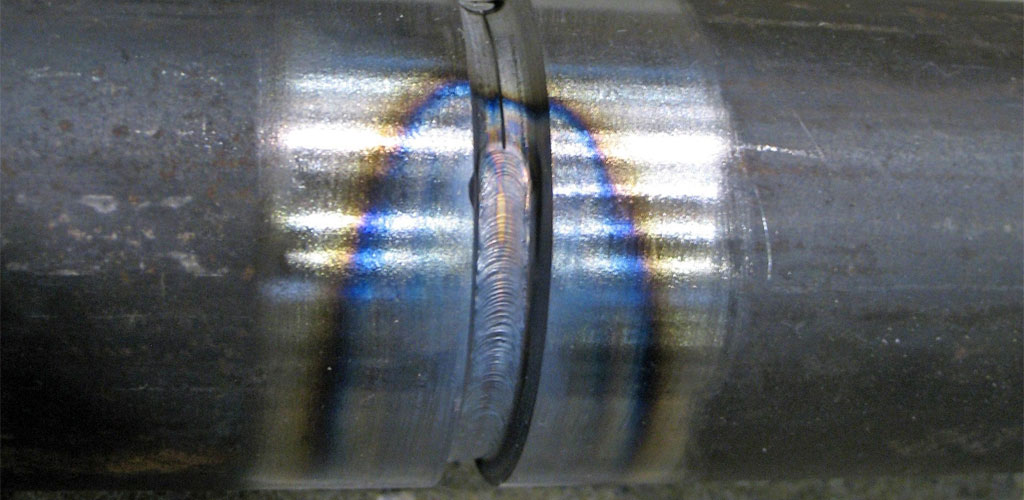

3. Undercut

The undercut appears as a groove or recess at the toe of the weld bead, compromising joint strength and aesthetics.

Causes: This defect often arises from excessive welding current, which can erode the base metal at the edges of the weld. Inadequate travel speed or incorrect electrode angle may also contribute to undercutting. The wrong type of filler material or insufficient filler deposition can exacerbate the problem, as can poor joint design that fails to accommodate heat flow.

Troubleshooting: Adjust welding parameters to maintain optimal heat input without eroding the base metal. Ensure a consistent travel speed and an appropriate electrode angle to promote even heat distribution. It may also be beneficial to redesign joints with better accessibility for the welding process, thereby reducing the likelihood of undercutting.

4. Incomplete Fusion

Incomplete fusion occurs when the two pieces of metal do not fully join together at the weld interface, leading to weak spots.

Causes: This defect is often a result of insufficient heat input, which prevents proper melting and bonding. Contamination at the joint surfaces, such as rust or paint, can hinder fusion. Additionally, improper joint design—such as insufficient gap or angle – can limit the welder’s ability to achieve full penetration and fusion.

Troubleshooting: Verify that welding parameters, including voltage and travel speed, are set to ensure adequate heat for proper fusion. Clean joint surfaces thoroughly before welding to remove contaminants. Consider redesigning the joint to improve accessibility and ensure effective fusion, particularly in complex geometries. If necessary, perform a root pass followed by filling passes to ensure thorough bonding.

5. Inclusion

Inclusions are non-metallic materials, such as slag or oxides, trapped within the weld bead, which can compromise the weld’s strength and integrity.

Causes: Inclusions often result from poor cleaning before welding, leaving contaminants on the base material. Inadequate technique that fails to remove slag from previous passes can also lead to inclusions. Furthermore, improper welding parameters, such as low heat settings, may not provide enough energy to expel impurities effectively.

Troubleshooting: Implement rigorous cleaning procedures for the base metal, including grinding or chemical cleaning, to ensure all contaminants are removed. After each welding pass, ensure thorough slag removal to prevent entrapment in subsequent layers. Adjust welding parameters to ensure sufficient heat input to allow for slag removal. Consider the use of advanced welding techniques or equipment that can better control the welding environment.

6. Overlap

Overlap occurs when the weld metal spreads over the base metal without adequate fusion, leading to a weakened joint.

Causes: This defect is typically caused by too low of a welding current, leading to insufficient heat for proper fusion. Poor technique, such as maintaining an incorrect electrode angle or travel speed, can further exacerbate the problem. Inadequate joint preparation may also prevent the molten metal from adequately penetrating and bonding with the base material.

Troubleshooting: Increase the welding current to ensure adequate heat input and promote proper fusion. Adjust the travel speed to allow sufficient time for the weld pool to penetrate the base material effectively. Ensure that the electrode angle is maintained correctly to facilitate proper molten flow. Evaluate joint preparation and redesign if necessary to enhance fusion opportunities.

7. Distortion

Distortion refers to the warping or bending of the workpiece as a result of welding, which can affect assembly and overall structural integrity.

Causes: This defect is primarily caused by uneven heating and cooling rates during welding, which creates internal stresses. The material properties, thickness, and joint design also influence susceptibility to distortion.

Troubleshooting: Employ preheating techniques to minimize temperature gradients, which can help control expansion and contraction. Balance heat input by strategically placing welds and using appropriate welding sequences. Using clamps, jigs, or fixtures can help maintain dimensional accuracy during the welding process and minimize movement. If distortion occurs, post-weld straightening techniques may also be employed.

8. Weld Spatter

Weld spatter consists of small droplets of molten material that scatter from the weld pool, potentially affecting the aesthetics and cleanliness of the finished product.

Causes: Excessive heat, incorrect voltage settings, and improper electrode position can all lead to increased spatter. Inconsistent travel speed or welding technique can also exacerbate the problem, as can the type and condition of the welding electrode.

Troubleshooting: Optimize welding parameters to achieve the correct balance of heat and travel speed. Use appropriate shielding gas to create a stable arc and reduce spatter. Regular maintenance of welding equipment can help minimize spatter issues and improve overall welding quality.

9. Heat Affected Zone (HAZ) Issues

HAZ issues arise in the area surrounding the weld that experiences changes in mechanical properties due to thermal effects, which can lead to compromised material strength.

Causes: Excessive heat input during welding can lead to altered microstructures in the HAZ, resulting in hardening or softening. The width and properties of the HAZ are influenced by the type of material, welding parameters, and cooling rate.

Troubleshooting: Control heat input carefully by adjusting welding parameters to minimize HAZ size and impact. Consider post-weld heat treatment to restore or enhance the mechanical properties of the HAZ. Select materials with favorable properties that can better withstand thermal effects. Employing controlled cooling methods can also help mitigate adverse HAZ issues, ensuring a more robust welded structure.

Final Words

Our skilled welders are trained to recognize and prevent common welding defects, ensuring that every weld meets the highest standards.

Whether you need structural welding or specialized fabrication, our excellent metal welding service enhances the integrity and durability of your projects.