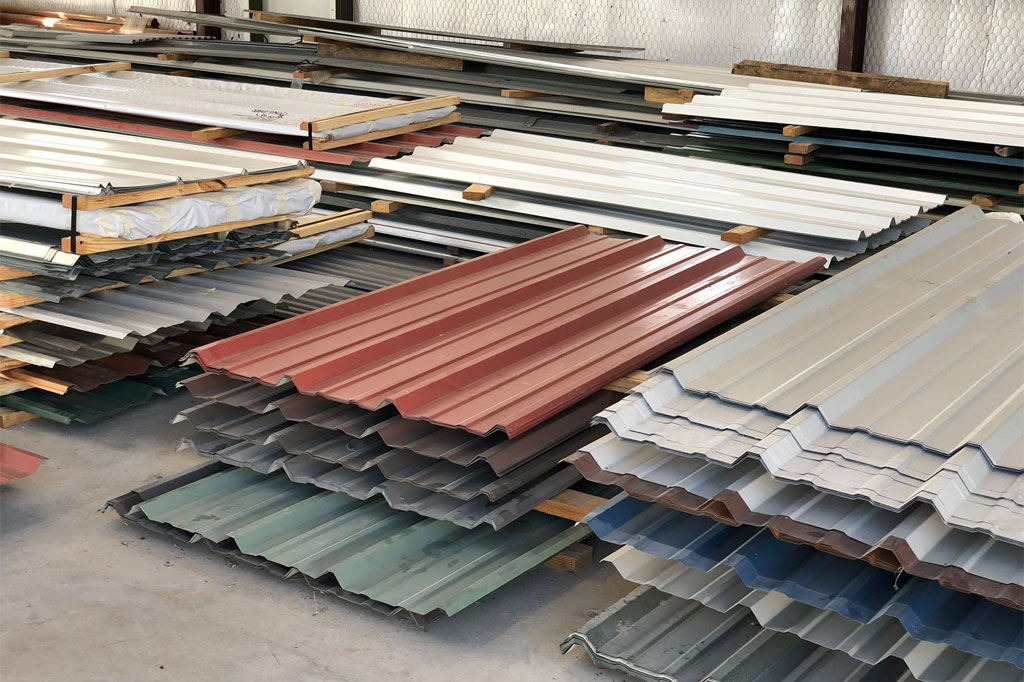

When it comes to cutting sheet metal, choosing the right method for your material is crucial to achieve clean, precise cuts and avoid material wastage.

Different metals, like aluminum, stainless steel, brass, and others, require specific cutting techniques to maintain their integrity and achieve the desired results.

In this article, we will explore the best methods for cutting 8 different types of sheet metal.

1. Best Way to Cut Aluminum Sheet

Aluminum is one of the most versatile metals used in sheet metal fabrication. It’s lightweight, durable, and easy to work with, but it requires special care when cutting to ensure clean edges and minimal distortion.

The best methods for cutting aluminum sheets include:

- Laser Cutting: Laser cutting is ideal for achieving precise, smooth edges with minimal burr formation. It also works well for both thin and thick aluminum sheets.

- Shearing: Mechanical shears can quickly cut through thinner aluminum sheets with clean, straight edges. This method is cost-effective for high-volume work.

- CNC Plasma Cutting: CNC plasma cutters are highly effective for cutting thicker aluminum sheets, offering both speed and precision.

2. Best Way to Cut Stainless Steel Sheet

Stainless steel is known for its strength, corrosion resistance, and sleek finish, but it can be challenging to cut due to its hardness. Choosing the right cutting method is key to achieving accurate cuts without damaging the material.

The best methods for cutting stainless steel sheets include:

- Laser Cutting: Laser cutting provides exceptional precision and smooth edges, making it ideal for intricate patterns and thin stainless steel sheets. It minimizes heat-affected zones and material distortion.

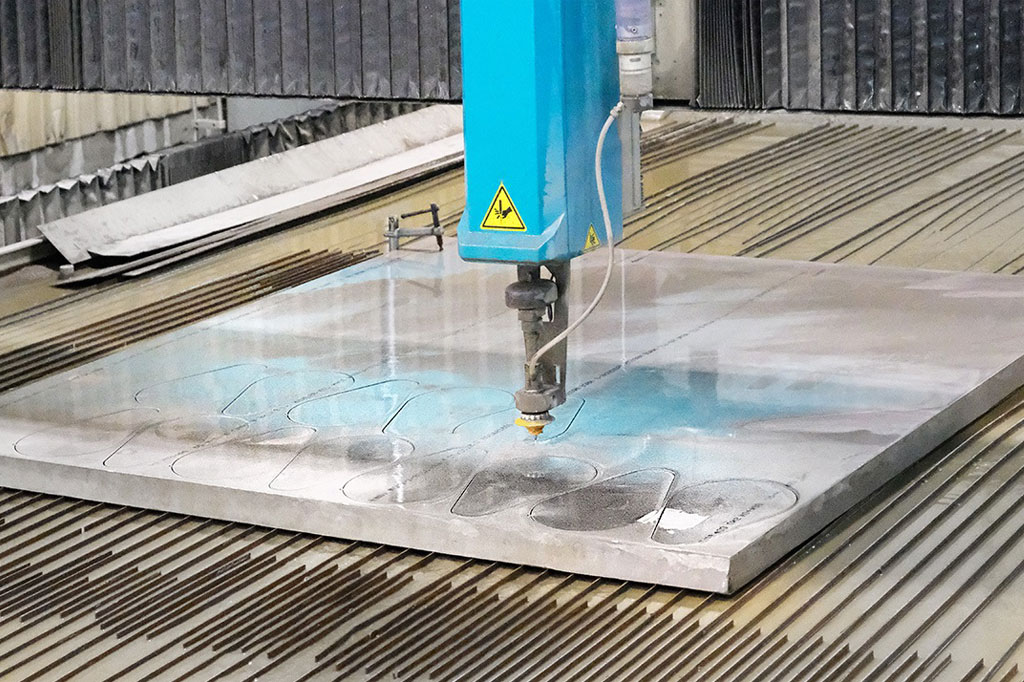

- Waterjet Cutting: For thicker stainless steel, waterjet cutting is a great option. It doesn’t generate heat, which prevents the material from warping or changing its properties.

- Plasma Cutting: Plasma cutting works well for thicker stainless steel sheets but may cause some edge oxidation, so additional finishing may be required.

- CNC Shearing: For straight cuts, CNC shearing is highly effective and offers high repeatability. Given the toughness of stainless steel, pre-heating and ensuring proper machine settings are important for quality cuts.

3. Best Way to Cut Brass Sheet

Brass is an alloy of copper and zinc, and its ductility allows it to be cut with relative ease compared to other metals. However, brass can become more difficult to cut when it’s thicker.

The best methods for cutting brass sheets include:

- Laser Cutting: Laser cutting is perfect for brass sheets, providing smooth and accurate cuts with minimal heat distortion. It’s ideal for both thin and thick brass.

- Shearing: For simple straight cuts, shearing works effectively on brass, especially when dealing with sheets of moderate thickness.

- Waterjet Cutting: Similar to stainless steel, waterjet cutting is effective for thicker brass sheets. It produces smooth edges without the risk of heat affecting the material. When cutting brass, ensure proper lubrication to avoid friction buildup, which can cause discoloration or damage to the material.

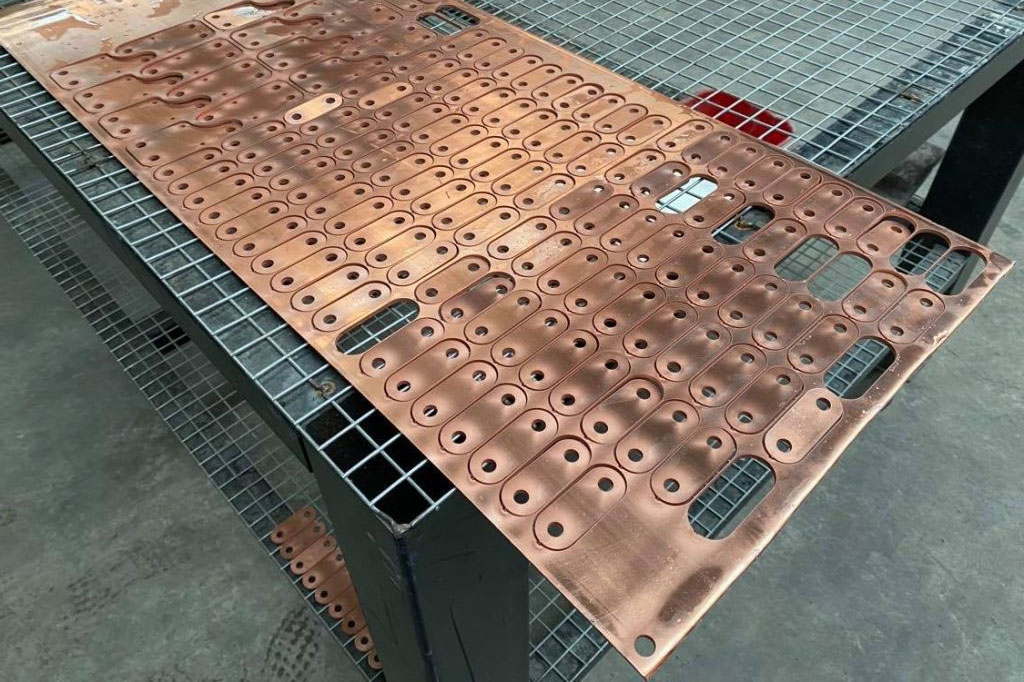

4. Best Way to Cut Copper Sheet

Copper is known for its excellent conductivity and malleability, but it can be tricky to cut because of its softness, which leads to edge deformation.

The best methods for cutting copper sheets include:

- Laser Cutting: Laser cutting provides clean and accurate cuts on copper, though it requires a high-powered system due to copper’s thermal conductivity. It’s ideal for intricate shapes and designs.

- Plasma Cutting: Plasma cutting works well for thicker copper sheets, but it can produce rough edges that may require post-processing.

- CNC Shearing: For straight cuts on thinner copper sheets, CNC shearing offers precision and minimal edge distortion. As copper can be prone to work hardening, it’s important to keep the cutting speed and pressure consistent.

5. Best Way to Cut Galvanized Steel Sheet

Galvanized steel, with its protective zinc coating, requires specific techniques to avoid damaging the coating.

The best methods for cutting galvanized steel sheets include:

- Shearing: Mechanical shears can be used for cutting galvanized steel sheets, offering fast and clean cuts while minimizing damage to the coating.

- Laser Cutting: Laser cutting is a preferred method for achieving smooth, clean edges without compromising the integrity of the zinc coating.

- CNC Plasma Cutting: Plasma cutting can effectively cut through thicker galvanized steel, but care should be taken to ensure the zinc coating does not degrade.

6. Best Way to Cut Titanium Sheet

Titanium is a strong, lightweight, and corrosion-resistant metal, but it’s more challenging to cut than aluminum or steel.

The best methods for cutting titanium sheets include:

- Waterjet Cutting: Waterjet cutting is the preferred method for titanium due to its ability to cut without heat, preventing material distortion and retaining the properties of the titanium.

- Laser Cutting: High-powered laser cutting can also be used to cut titanium, but it requires careful control of heat input to prevent discoloration and material weakening.

- CNC CNC Shearing: CNC shearing works well for titanium sheets with thinner gauges, providing a clean and precise edge. Proper cutting speeds and coolants are essential when cutting titanium to avoid damage to the material or tools.

7. Best Way to Cut Nickel Sheet

Nickel, like titanium, is a tough material with high resistance to heat and corrosion. Cutting nickel sheets effectively requires tools that can handle its toughness without causing excessive tool wear.

The best methods for cutting nickel sheets include:

- Waterjet Cutting: Waterjet cutting is ideal for nickel, as it can easily handle the material’s toughness and thickness while avoiding heat buildup.

- Laser Cutting: Laser cutting is also effective for thinner nickel sheets, providing smooth, precise cuts with minimal heat-affected zones.

- Plasma Cutting: Plasma cutting can be used for thicker nickel sheets but may result in rough edges and increased post-processing requirements. It’s important to control cutting speeds and feed rates to avoid excessive friction and tool wear when working with nickel.

8. Best Way to Cut Iron Sheet

Iron is a relatively simple material to cut, but it requires the right tools to ensure smooth, precise cuts.

The best methods for cutting iron sheets include:

- Shearing: Shearing is a common method for cutting iron sheets, especially for thinner gauges. It provides clean, straight cuts and is effective for large volumes.

- CNC Plasma Cutting: Plasma cutting can be used for thicker iron sheets, providing both speed and precision, though it may require post-processing for smooth finishes.

- Laser Cutting: Laser cutting offers precise, high-quality cuts for iron sheets, especially for intricate designs.