Sheet metal bending is a critical process in the manufacturing of various products, from automotive parts to consumer electronics. The cost of sheet metal bending can vary significantly based on several factors, and understanding these factors is essential for manufacturers seeking to optimize their production process and reduce costs.

In this article, we will break down the key factors that affect the costs of sheet metal bending, along with strategies for reducing them.

10 Factors Affecting Sheet Metal Bending Costs

Sheet metal bending costs are influenced by various factors, such as materials, bending complexity, tolerance requirements, volume, tooling & labor costs, and additional post-bending process. Understanding these factors can help manufacturers accurately estimate costs and plan for efficient production.

1. Material Type

The material chosen for sheet metal bending significantly determines the costs. Common materials like aluminum, steel, stainless steel, and copper vary widely in price due to factors such as market demand, material properties, and availability.

- Steel: Mild steel is typically the least expensive option, with prices ranging from $0.70 to $1.50 per pound.

- Aluminum: Aluminum tends to be more expensive, with a price range of $1.60 to $2.80 per pound depending on the alloy and grade.

- Stainless Steel: Stainless steel is more expensive, ranging from $2.00 to $4.50 per pound.

- Copper: Copper is the most expensive, with prices often ranging from $3.00 to $5.00 per pound.

The cost difference is primarily attributed to material processing, availability, and mechanical properties such as strength, corrosion resistance, and weight.

2. Thickness of Material

The thickness of sheet metal significantly affects bending costs, influencing both material expenses and the complexity of the bending process. Thicker materials require more powerful machinery, longer processing times, and more precise bending controls, increasing labor and tooling costs.

- Thin materials (under 1mm) are typically cheaper to bend and faster to process.

- Materials with thicknesses over 6mm may require special equipment (like hydraulic press brakes), increasing the cost due to the complexity of the operation.

As the thickness increases, you may need to consider specialized tooling or machine upgrades, further raising the cost.

Cost Estimation Comparison Chart by Material and Thickness

Material | Thickness Range | Cost Range (per part) | Notes |

Mild Steel | 0.5mm - 6mm | $1 to $4 | Most cost-effective for general bending |

Stainless Steel | 0.5mm - 6mm | $2 to $8 | Strong, but more expensive due to alloying elements |

Aluminum | 0.5mm - 5mm | $2 to $6 | Lightweight, but pricier for bending and tooling |

Copper | 0.5mm - 6mm | $3 to $10 | Expensive, used in specialized applications |

Brass | 0.5mm - 5mm | $3 to $9 | Generally higher material cost, used for decorative or specialized parts |

3. Bending Complexity

The complexity of the bends, including the number of bends, their angles, and the shape of the part, can drive up the cost. Simple bends (such as 90-degree angles) are typically less expensive, while more intricate bends (e.g., multiple radii, compound bends) increase the setup and machining time.

For example, a simple 90° bend might cost between $0.10 and $0.20 per part, while a double bend or complex multi-bend part could raise the cost to between $0.30 and $0.80 per part.

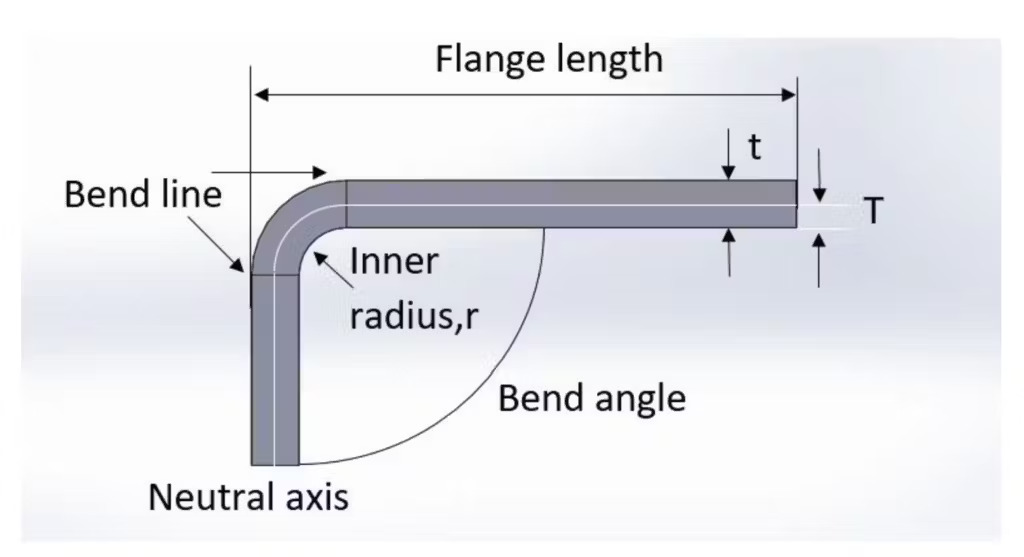

4. Bend Radius and Tolerances

Tighter tolerances and smaller bend radii require more precision, which demands more advanced machinery and potentially longer processing times. Standard tolerances may range from ±0.5 mm to ±1.0 mm, but tighter tolerances (e.g., ±0.2 mm) will require more advanced equipment and processes, resulting in increased costs.

- Standard bend radius: For most materials, a 1x material thickness radius (e.g., for a 2mm thickness material, a 2mm radius) is common.

- Tight tolerance parts: Achieving ±0.1 mm tolerance can increase costs due to more precise control during the bending process.

5. Volume of Production

The production volume has a direct effect on the cost per unit. In high-volume production, economies of scale come into play, as setup costs are distributed over a larger number of parts, lowering the cost per unit. In contrast, low-volume or prototype runs lead to higher per-unit costs due to the increased setup and tooling time.

- Low-volume production: Typically has a higher per-unit cost because each part requires setup, adjustments, and retooling.

- High-volume production: Costs can be reduced significantly. For example, a batch of 1,000 units could lower the per-part price from $1.50 to $0.60.

6. Bending Technology Used

The type of equipment used for sheet metal bending can significantly influence cost. Traditional methods like manual press brakes are less expensive upfront but require more labor and time.

On the other hand, advanced automated systems like CNC press brakes offer higher precision and faster production but come with higher initial investments.

- Manual press brake: Approximate cost per part is $0.10 to $0.25 for simple bends.

- CNC press brake: Cost per part can be around $0.20 to $0.50 depending on the complexity.

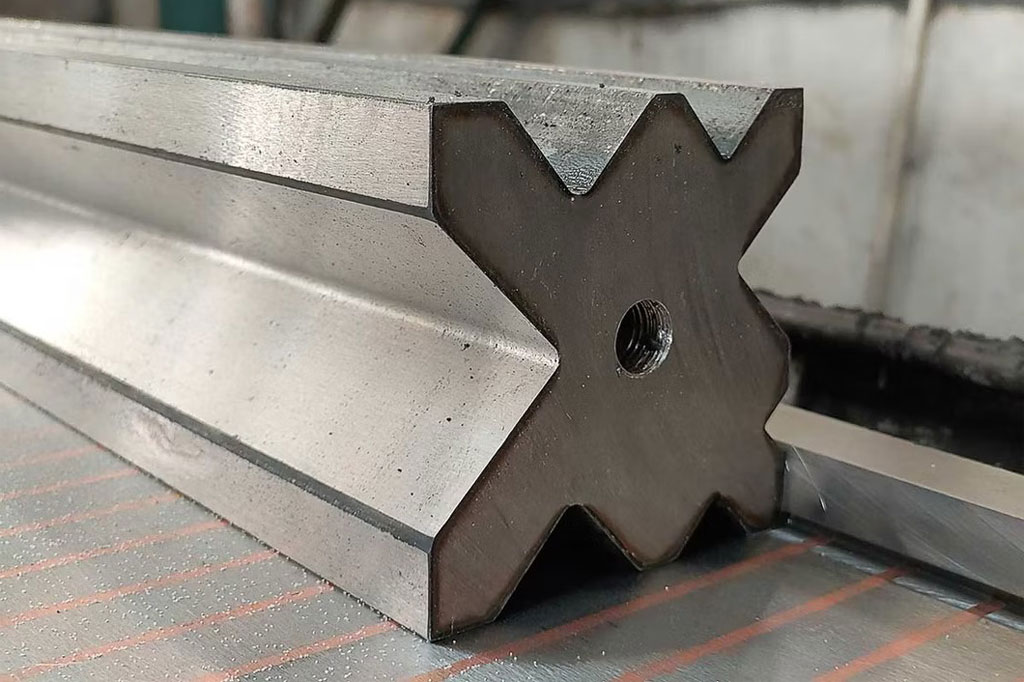

7. Dies or Tooling Cost

Tooling refers to the specific dies and punches used in the bending process. The cost of dies varies based on the material, the complexity of the bend, and the quantity required. Custom dies can be quite expensive but may reduce labor time for large-scale production.

- Standard die sets: Cost around $200 to $500 per set.

- Custom die sets: Can cost anywhere from $1,000 to $5,000, depending on the complexity.

Tooling costs are amortized over high-volume runs, making them less impactful in large batches but costly in small production runs.

8. Labor Costs

Manual labor costs for skilled workers typically range between $25 to $60 per hour, while automated systems reduce the number of required operators, but may still involve setup and maintenance labor costs.

- Manual operation: Labor-intensive, requiring a skilled worker.

- Automated operation: Reduces labor costs but requires specialized knowledge to operate CNC systems.

9. Post-Bending Processing

After the bending process, there may be additional steps required, such as cutting, punching, welding, or cleaning. Post-processing activities can add additional costs depending on the complexity of the work.

- Deburring and cleaning: This can cost an additional $0.05 to $0.20 per part.

- Additional machining or modifications: Can add $0.50 to $3.00 per part.

10. Finishing and Surface Treatment

Finishing processes, such as painting, coating, or anodizing, are often necessary to protect the metal or provide aesthetic qualities. These processes can significantly add to the cost, especially when dealing with complex or multi-step finishes.

- Powder coating: Typically adds $0.50 to $3.00 per part.

- Anodizing: This can range from $1.00 to $5.00 per part, depending on the material and finish quality.

5 Ways to Reduce Sheet Metal Bending Costs

By selecting cost-effective materials, optimizing designs for simpler bends, increasing production volume, automating processes, and outsourcing to regions with lower labor costs, manufacturers can achieve significant savings while maintaining part quality and precision.

1. Choose the Right Material

Choosing a material that is cost-effective for your specific requirements can significantly reduce costs. For example, mild steel is typically the least expensive material, while stainless steel or titanium can be much more costly. Balancing material cost with performance and durability is key.

- Opt for mild steel for non-corrosive applications.

- Aluminum is an excellent choice when weight reduction is necessary but should be chosen carefully based on its alloy grade.

2. Optimize Design for Bending

Designing parts with fewer bends and avoiding tight radii or complex geometries can reduce bending costs. The more complex the design, the more setup time and tooling may be required. Standard bend angles (e.g., 90° bends) and larger radii can help minimize the need for custom tooling.

- Aim for 1.5x to 2x material thickness radii for standard bends to avoid the need for specialized tooling.

- Minimize the number of bends by optimizing part design and layout.

3. Automate the Process

Implementing automated systems such as CNC press brakes or robotic arms can significantly reduce labor costs, improve precision, and speed up production times. Although initial investments can be high, automation pays off in high-volume runs.

Automated systems reduce labor time by as much as 30% to 50% compared to manual operations.

4. Increase Production Volume

Increasing production volume allows you to spread the setup and tooling costs across more parts, which can significantly lower the cost per unit. High-volume production also improves efficiency, making it possible to complete parts faster.

5. Outsource to Low-Cost Regions

Outsourcing sheet metal bending operations to countries with lower labor costs can result in significant savings. Countries like China, India, and Mexico are known for their competitive manufacturing costs, including lower labor expenses and material costs.