Metal Stamping Service

- Our advanced stamping technology and experienced team ensure precision and reliability in every project, whether it's for small or large production runs.

- Our services are adaptable to various materials, including aluminum, stainless steel, copper, brass, nickel and more.

- From custom die design to specific material requirements, we can accommodate various customization requests to align with your project’s unique needs.

- Various Stapming Types

- Maximum 400 Tons Press Rating

- 0.004" ~ 0.47" (0.1mm ~12mm) Metal Thickness

- ±0.01"(0.25mm) Tight Tolerance

- Custom Dies & Punches for Your Designs

1. Send Your Drawings

Begin by providing detailed drawings or CAD files of the part you need to be stamped. This helps us accurately understand the design and requirements.

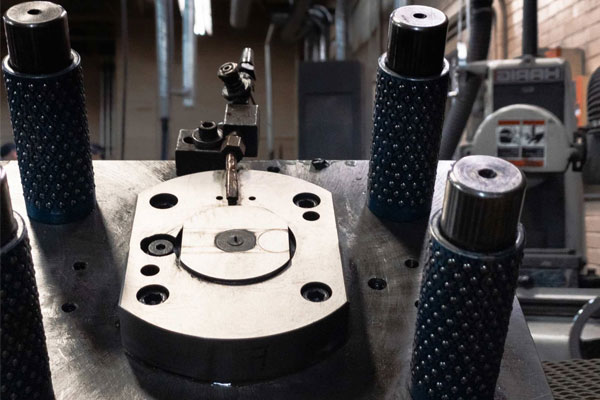

2. Design & Engineering Support

Our engineering team reviews the drawings, and provides feedback. Then, specialized tools and dies are created based on the final proven design.

3. Sheet Metal Preparation

Prepare the sheet metal for stamping by cutting it into the appropriate size and ensuring it is free of defects.

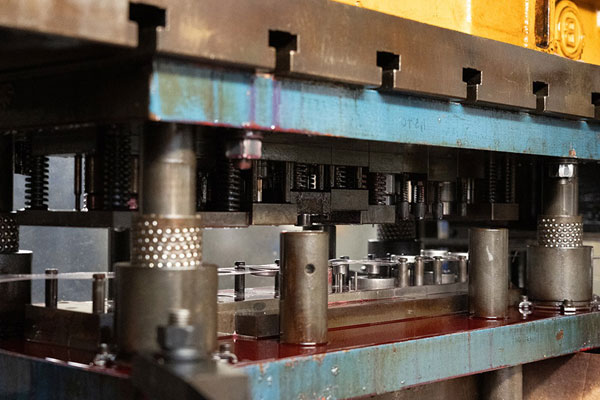

4. Stamping Press

Applying force to the metal to form the desired shape. It can include processes such as blanking, punching, bending, or coining.

5. Post-Processing

After stamping, the parts may require additional processing, such as trimming excess material, deburring, or adjusting dimensions to ensure they meet specifications.

6. Surface Finishing

Finally, the stamped parts are finished with surface treatments like painting, plating, or coating to enhance durability, appearance, or corrosion resistance.

Our Metal Stamping Process

Our Stamping Types

Progressive Die Stamping

- It involves a series of stations on a single die, the material progresses through each station with each press cycle.

- Allows for intricate designs, making it perfect for components requiring multiple operations in a single pass.

Transfer Die Stamping

- The transfer system transports the partially processed material between dies from one station to another.

- Particularly useful for large or irregularly shaped parts that require multiple stages of stamping.

Compound Die Stamping

- It involves a single die with multiple operations (e.g., cutting and bending) performed in one stroke.

- Highly efficient for creating components with simple designs, delivering consistent quality and fast turnaround times.

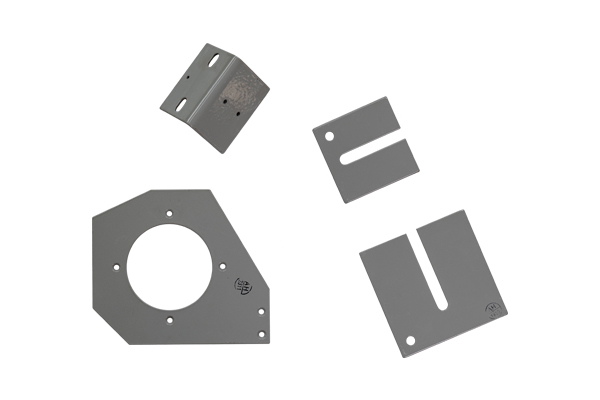

Our Metal Stamping Parts