Metal Enclosure Manufacturer

- From design to delivery, we produce high-quality metal enclosure boxes tailored for electrical, electronics, and more.

- Durable, precise, and fully customizable. Request a quote now!

- Aluminum & Steel Material Options

- Built to Your Specs

- Precision Crafted

- Quality Surface Finishes

By Materials

We manufacture custom metal enclosures from aluminum, stainless steel (304/316), mild steel, galvanized steel, and carbon steel. Choose the material based on the application’s environmental conditions, strength requirements, and budget constraints.

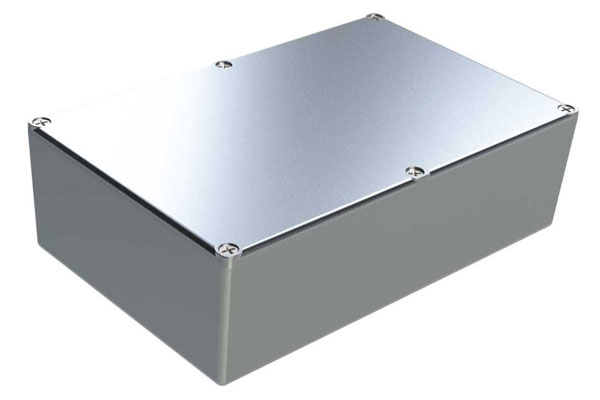

Aluminum Enclosure

Lightweight and corrosion-resistant, aluminum enclosures are ideal for outdoor applications, offering excellent thermal conductivity and customization options for electronic uses.

304 Stainless Steel Enclosure

304 stainless steel enclosures provide outstanding corrosion resistance, and strength, suitable for hygienic environments, such as food and pharmaceutical applications.

316 Stainless Steel Enclosure

With superior corrosion resistance, 316 stainless steel enclosures excel in harsh chemicals, saltwater, and extreme environments, ensuring long-lasting performance and reliability.

Mild Steel Enclosure

Galvanized Steel Enclosure

Carbon Steel Enclosure

By Installation Methods

When selecting a metal enclosure box installation type, consider the application environment for durability, space availability for proper fit, mobility for relocation needs, and aesthetics to match design preferences.

Free Standing Enclosure

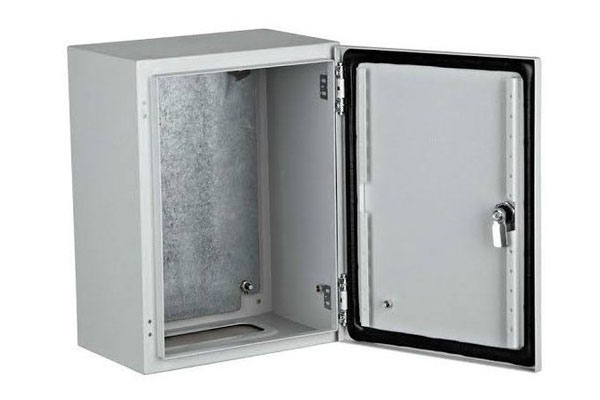

Wall Mount Enclosure

Flush Mount Enclosure

Seamlessly integrated, flush mount enclosures provide a sleek and space-efficient solution, ideal for applications requiring minimal protrusion in walls or panels, ensuring easy access and aesthetic appeal.

Rack Mount Enclosure

By Applications

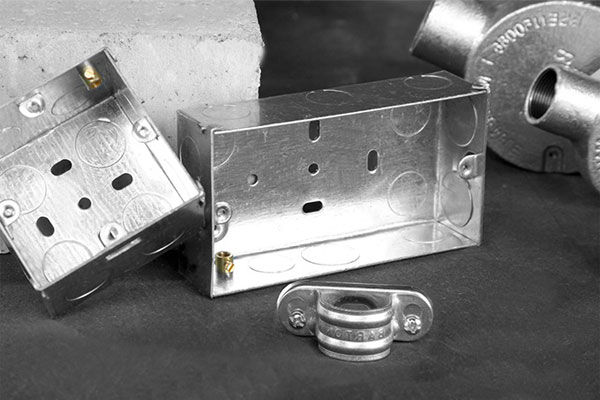

Metal Socket Box

Metal Adaptable Box

Metal Generator Enclosure

Metal Junction Box

Busbar Panel Box

MCB Metal Box

High-quality enclosures for miniature circuit breakers, designed for secure mounting, easy access, and reliable protection in residential and industrial electrical systems.

Electrical Cabinet

Battery Enclosure

Durable and ventilated enclosures for batteries, designed to provide safety, thermal management, and protection from environmental conditions in energy storage systems.

By IP Ratings

By understanding the level of protection required for your outdoor applications, you can choose the right IP-rated metal enclosure box to ensure safety and reliability.

IP65 Metal Enclosure

- Fully dust-tight.

- Protects against low-pressure water jets from any angle (low-pressure water streams, 6.3 mm nozzle).

- Best for protection against dust and basic water splashes.

IP66 Metal Enclosure

- Fully dust-tight.

- Protects against powerful water jets from any direction (100 kPa high-pressure water streams, 12.5 mm nozzle).

- Suitable for heavy outdoor exposure or industrial cleaning environments.

IP67 Metal Enclosure

- Fully dust-tight.

- Protects against temporary immersion in water (up to 1 meter for 30 minutes)

- Ideal for equipment exposed to occasional immersion or wet conditions.

IP68 Metal Enclosure

- Fully dust-tight.

- Designed for continuous immersion in water at specified depths and durations. Depth ratings vary by manufacturer.

- Required for underwater or high-moisture applications.

By Manufacturing Process

Choosing the right manufacturing process for metal enclosures depends on factors like complexity, material, cost, and volume. Sheet metal is ideal for custom shapes, while extrusion suits long profiles, and die casting offers precision for complex parts.

Sheet Metal Fabricated

- Created by cutting, bending, assembling metal (steel, aluminum, and stainless steel are common options) sheets.

- Can accommodate various customizations in terms of mounting features, cutouts for ports or buttons, and holes for ventilation.

- More assembly (such as welding or fastening) is required.

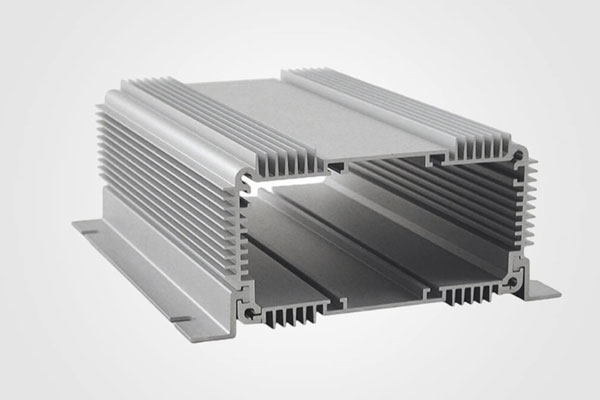

Extruded

- Pushed aluminum through a mold to form continuous profiles with a consistent cross-section, then cut to length after extrusion.

- Ideal for simple, long enclosures with basic rectangular or square cross-sectional profiles.

- Faster production for high volumes.

Die Casted

- Typically aluminum, zinc, or magnesium alloys.

- Excellent for producing intricate shaped enclosures with thin walls and precise dimensions.

- Fine details and smooth surfaces can be achieved without the need for additional machining.

- Highly cost-effective for large-volume production.