EDM Machining Service

- We are a leading provider of EDM (Electrical Discharge Machining) services.

- Our EDM process offers exceptional accuracy for complex parts and intricate geometries, and reduces the need for secondary finishing.

- Wire / Sinker / Hole Drilling EDM

- Multi-axis Controls

- Works on Hardened & Conductive Materials

- High Precision & Tight Tolerances

- Excellent Surface Finish

- Provide Customized EDM Solutions

1. Setup

A tool electrode (typically made from copper, graphite, or tungsten) and a workpiece are submerged in a dielectric fluid, often deionized water or oil. CNC control systems guide the movement of the electrode to follow the desired shape.

2. Spark Generation

A controlled electrical discharge (spark) is generated between the tool electrode and the workpiece, creating intense heat (8,000-12,000°C).

3. Material Removal

The heat from the sparks vaporizes a small portion of the workpiece material at the spark contact point. The removed material is carried away by the dielectric fluid.

4. Repetition

Thousands of sparks are generated per second, which gradually erodes the material to the desired shape.

5. Final Result

This method allows for extremely fine cuts and precision, even on materials like hardened steel, titanium, and superalloys.

Our EDM Machining Process Overview

Our EDM Machining Options

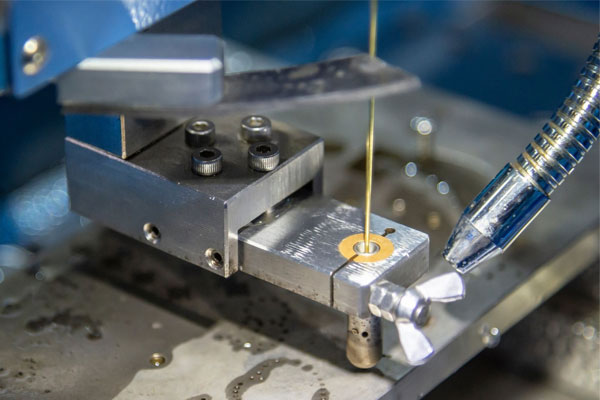

Wire EDM

- Uses a thin, electrically charged brass wire to cut materials by creating electrical sparks between the wire and the workpiece.

- Can cut through hard materials like tool steel, titanium, and tungsten carbide.

- ±0.001"(0.025mm) ~ ±0.0005"(0.0127mm) tolerance.

- Best for precision cutting of 2D shapes.

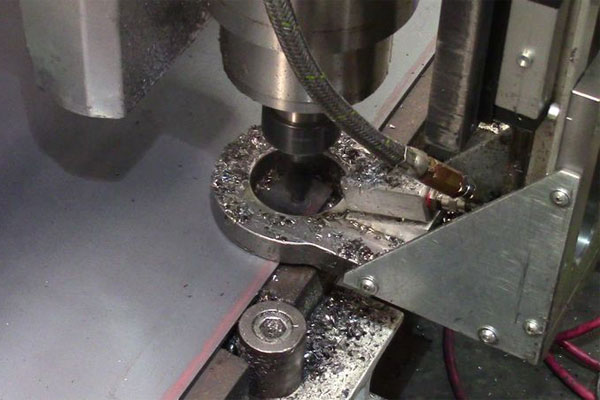

Sinker EDM

- A shaped copper or graphite electrode is used to erode the workpiece in a predefined shape through electrical discharge.

- Suitable for hard metals like stainless steel, carbide and Inconel superalloys.

- ±0.002"(0.05mm) ~ ±0.0005"(0.0127 mm) tolerance.

- Ideal for creating complex 3D geometries and molds.

Hole Drilling EDM

- Uses a small, rapidly rotating electrode tube to create deep, small-diameter holes with high precision in hard conductive materials.

- Can drill in materials that are too hard for conventional drilling.

- ±0.001"(0.025mm) ~ ±0.002"(0.0508 mm) tolerance.

- Extremely fast for precise small & deep hole drilling.

Materials For EDM

The materials suitable for EDM machining can be broadly categorized into hard metals, conductive metals, and others, each encompassing specific materials with unique properties.

Hard Metals

Conductive Metals

Non-metals

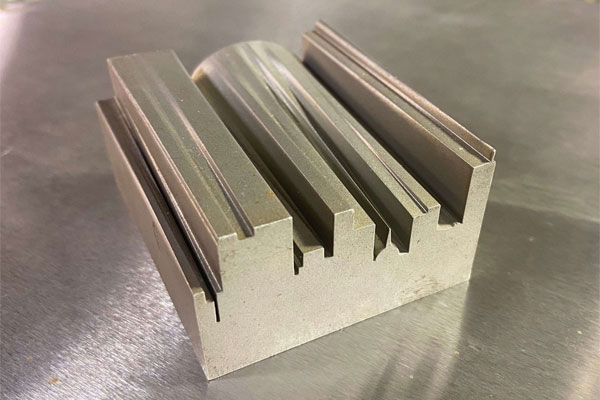

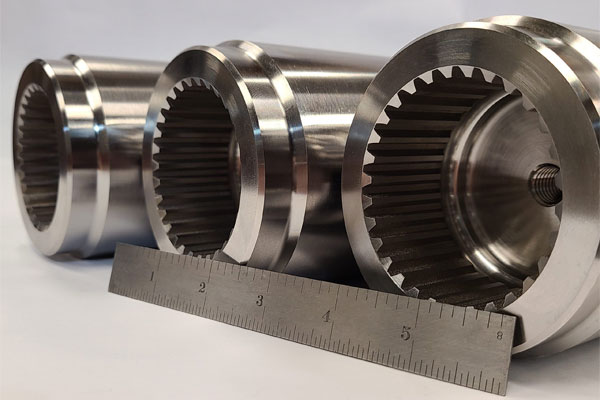

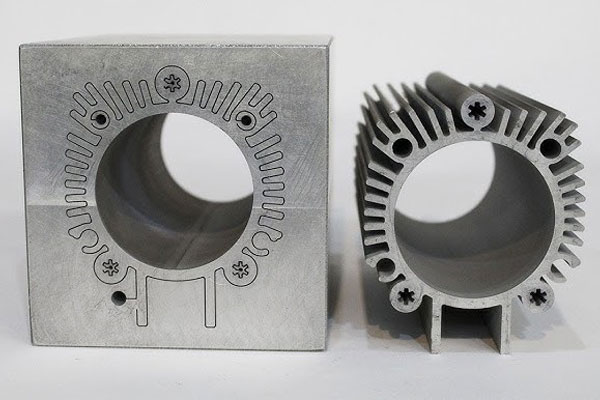

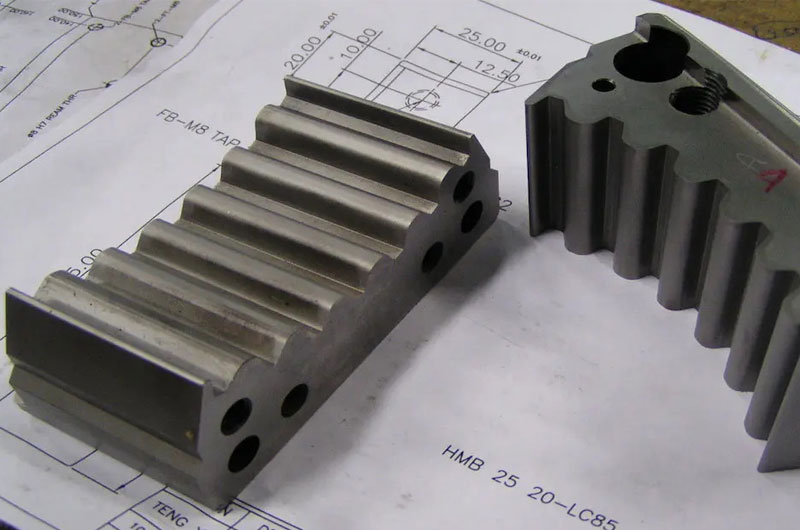

Our EDM Projects