Die casting is vital for creating intricate metal parts with high precision and quality. It is prone to flaws, though, which could compromise the final product’s functioning and integrity. Understanding these defects and their solutions is essential for manufacturers to enhance quality and maintain a competitive edge.

This guide explores common die casting defects and practical solutions to address them.

Common Die Casting Defects

Common die casting defects include porosity, cold shuts, flash, shrinkage, misruns, and blisters, each requiring specific solutions to enhance product quality and ensure the integrity of the final cast parts.

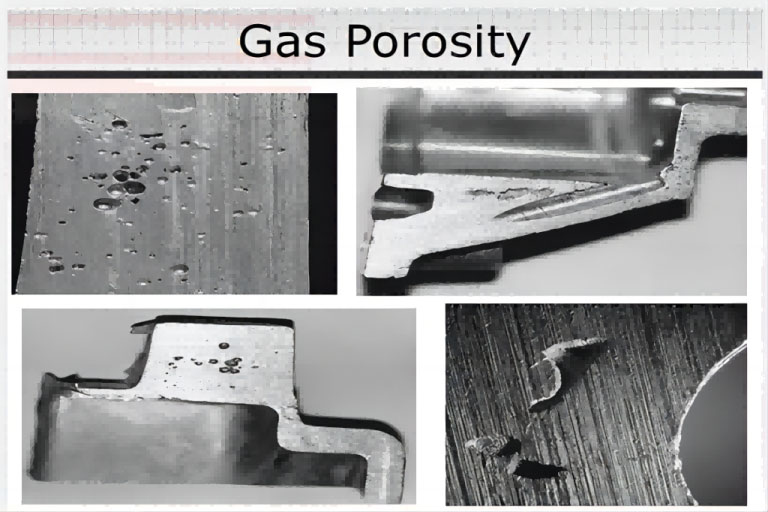

Porosity

Porosity, characterized by small voids or holes within the metal, is a prevalent defect in die casting. It takes place when gas gets trapped in the metal during solidification. Porosity can lead to weakened structural integrity and compromised surface quality.

Several focused approaches can be used to effectively address porosity.

- Optimize Gating and Venting Systems: Proper design and placement of gates and vents ensure efficient gas escape, reducing the risk of porosity.

- Vacuum Die Casting: Using vacuum-assisted die casting can significantly reduce trapped gases.

- Control Process Parameters: Maintain optimal temperature and pressure throughout the casting process to minimize gas entrapment.

Cold Shuts

Cold shuts appear as lines or seams on the casting surface, resulting from the premature solidification of metal before the mold cavity is fully filled. This defect can weaken the part and affect its appearance.

To effectively address cold shuts and ensure a seamless finish, consider implementing these targeted solutions.

- Increase Mold Temperature: A higher mold temperature ensures better metal flow and reduces the likelihood of cold shuts.

- Adjust Injection Speed and Pressure: Proper control of these parameters helps achieve complete mold filling without premature solidification.

- Design Improvements: Optimize the mold design to promote smooth and continuous metal flow.

Flash

Flash is excess material that appears along the parting line or around ejector pins, typically caused by high injection pressure or worn-out molds. While it can be removed, it adds extra processing time and cost.

To effectively reduce flash and improve efficiency, several targeted solutions can be implemented.

- Maintain Injection Pressure: Use appropriate injection pressure to prevent excess material formation.

- Regular Mold Inspection: Inspect and repair molds regularly to prevent wear that can lead to flash.

- Precision Machined Molds: Use high-quality, precision-machined molds to reduce the occurrence of flash.

Shrinkage

Shrinkage defects manifest as cavities or depressions on the casting surface, caused by the reduction in metal volume as it cools and solidifies. This can compromise the part’s dimensional accuracy and strength.

To mitigate shrinkage defects and enhance the quality of cast parts, consider implementing these effective solutions.

- Proper Mold Design: Ensure the mold allows for adequate feeding during solidification to compensate for volume reduction.

- Use of Chills: Chills can be employed to control the cooling rate and minimize shrinkage.

- Optimized Gating System: Design the gating system to ensure consistent metal flow and feeding.

Hot Tearing

Hot tearing occurs when the metal solidifies unevenly, leading to cracks or fractures in the die-cast part. These cracks often appear along the part’s edges or in areas where the metal has difficulty flowing.

Solutions for die-casting hot tearing defects include optimizing cooling rates, improving mold design, and adjusting alloy composition.

- Reduce Cooling Rate: Slowing down the cooling rate allows the metal to solidify more uniformly, reducing the chances of hot tearing.

- Improve Alloy Composition: Using an alloy with better fluidity and lower shrinkage characteristics can help reduce the formation of hot tears.

- Enhance Mold Design: Modifying the mold to reduce sharp corners and thin sections can help improve the metal’s flow, minimizing stress and the likelihood of cracking.

Dimensional Inaccuracy

Dimensional inaccuracy refers to the failure of the die-cast part to meet the specified dimensions, often due to variations in mold cavity dimensions or inconsistent cooling rates.

Solutions for die casting dimensional inaccuracy include precise mold design, optimized cooling rates, and proper mold maintenance.

- Tighten Mold Tolerances: Ensuring the mold cavity is precisely machined and regularly maintained is essential for producing parts within the desired tolerance limits.

- Control Cooling Rates: Controlling the cooling rate by using water channels and cooling systems in the mold can help prevent warping and shrinkage.

- Conduct Proper Mold Maintenance: Regular maintenance, including inspecting for wear and tear, ensures that the mold retains its accuracy over time.

Misruns

Misruns occur when the metal solidifies before completely filling the mold cavity, resulting in incomplete parts. This defect can be due to insufficient pouring temperature, inadequate mold venting, or improper injection speed.

Take into consideration the following practical strategies to handle errors and guarantee full mold filling.

- Increase Pouring Temperature: Ensure the metal is at the correct temperature for complete mold filling.

- Adequate Mold Venting: Proper venting allows gases to escape, preventing premature solidification.

- Adjust Injection Speed and Pressure: Optimize these parameters to ensure consistent and complete mold filling.

Blisters

Blisters are raised areas on the casting surface caused by trapped gas or contaminants. They can affect the surface finish and, in some cases, the structural integrity of the part.

To effectively reduce the occurrence of blisters, several targeted solutions can be applied.

- Improve Mold Venting: Ensure the mold is adequately vented to allow trapped gases to escape.

- Clean Raw Materials: Use clean and dry raw materials to prevent contamination.

- Control Temperatures: Maintain optimal mold and metal temperatures to reduce the risk of gas entrapment.

Advanced Solutions and Best Practices

To effectively combat die casting defects, manufacturers should implement the following best practices:

- Regular Mold Maintenance: Perform routine inspections and upkeep of molds to prevent wear and tear that could cause defects. This involves inspecting for cracks, wear, and other damages that could impact mold performance.

- Process Control: Implement advanced monitoring systems to regulate temperature, pressure, and other crucial parameters during the casting process. Automated systems can provide real-time feedback and adjustments, ensuring consistent quality.

- Training and Expertise: Ensure that operators and engineers are well-trained in die casting techniques and defect prevention strategies. The workforce is kept up to date with the newest best practices and technologies through ongoing education and training.

- Quality Assurance: Implement rigorous quality control measures, including non-destructive testing (NDT), to detect and address defects early in the production cycle. Techniques such as X-ray inspection, ultrasonic testing, and dye penetrant inspection can help identify defects that are not visible to the naked eye.

Conclusion

Die casting defects can impact metal part quality and performance, but with the right solutions and best practices, manufacturers can minimize these issues. Identifying defect causes and applying advanced techniques ensures high quality and reliability in the industry.

Regular mold maintenance, process control, training, and quality assurance enhance die casting operations, improving product quality, reducing waste, and increasing customer satisfaction.