In modern manufacturing, selecting the right production method—CNC machining, sheet metal fabrication, or die casting – is crucial for a project’s success. Each method impacts quality, cost, and efficiency differently.

Here, we delve into the advantages and disadvantages of each method to help you determine the best fit for your specific needs.

Three Manufacturing Methods Comparison

Criteria | CNC Machining | Sheet Metal Fabrication | Die Casting |

Material Compatibility | Metals, Plastics, Composites | Metals | Metals (Zinc, Aluminum, Magnesium) |

Precision | High | Moderate | Moderate to High |

Production Volume | Low to Medium | Medium to High | High |

Cost Efficiency | Moderate to High | High for large volumes | High for large volumes |

Lead Time | Short to Medium | Short | Medium to Long |

Design Complexity | High | Low to Moderate | High |

Tooling Cost | Low | Moderate | High |

Surface Finish | Good | Fair to Good | Excellent |

Typical Applications | Prototypes, Low-volume Production, Complex Parts | Enclosures, Brackets, Panels | High-volume Production, Automotive Parts, Housing |

CNC Machining

CNC machining delivers high precision and tight tolerances, perfect for crafting detailed and complex parts. It is capable of working with metals, plastics, and composites, making it suitable for creating prototypes and custom designs.

However, it has higher costs, slower production for large volumes, and significant material wastage, making it less economical for extensive runs despite ensuring consistent results.

Pros | Cons |

|

|

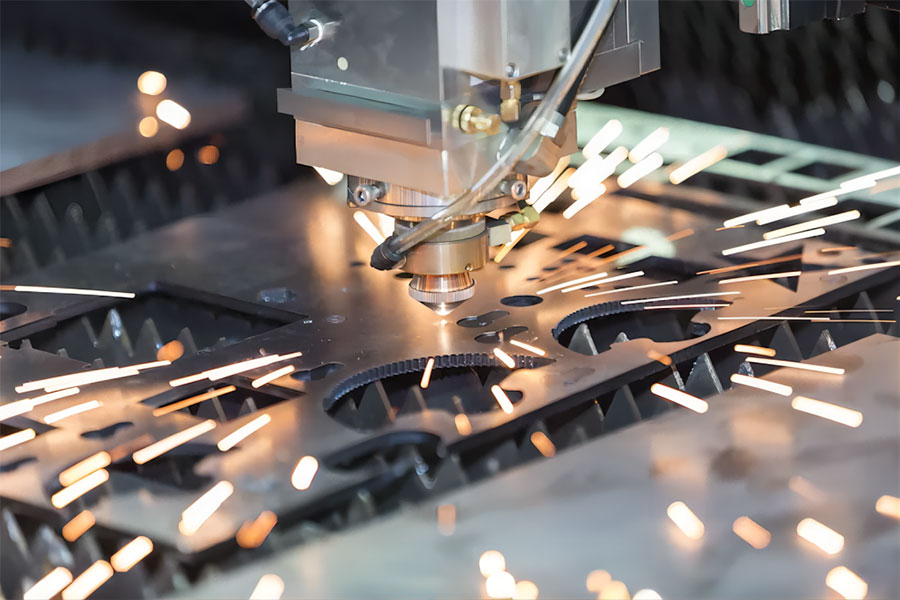

Sheet Metal Fabrication

Sheet metal fabrication is cost-effective for medium to large runs, producing strong, durable parts quickly. It handles various metal types and thicknesses but is limited to simpler geometries and metal sheets.

While not as precise as CNC machining, it efficiently produces straightforward, robust components for structural applications, offering quick production times and versatility in metal handling.

Pros | Cons |

|

|

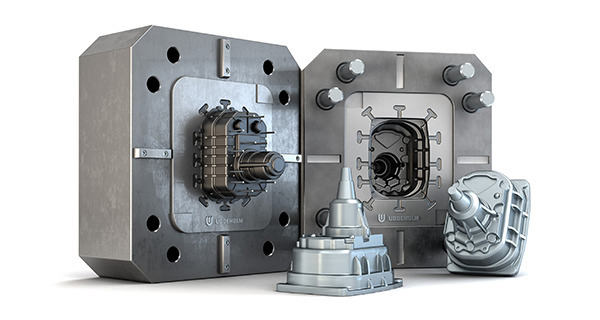

Die Casting

Die casting is efficient for large-volume production, lowering per-unit costs. It creates detailed parts with superior surface finishes and a high strength-to-weight ratio, predominantly using non-ferrous metals such as aluminum and zinc.

High initial setup costs and longer setup times are involved due to molds and tooling, but it remains the most economical for complex, large-scale production.

Pros | Cons |

|

|

Which Method is Right for Your Project?

The choice between CNC machining, sheet metal fabrication, and die casting depends on various factors including the complexity of the design, the type of material, the production volume, and cost considerations.

- Precision and Complexity: If your project requires high precision and complex designs, CNC machining is the best option.

- Cost and Speed for Medium Runs: For medium to large production runs where cost and speed are critical, sheet metal fabrication is a practical choice.

- Large Volume and Intricate Designs: For large volume production and intricate parts with excellent surface finishes, die casting stands out as the most efficient method.

In Conclusion

Every manufacturing method has its unique benefits and is suitable for specific project requirements. By understanding the strengths and limitations of CNC machining, sheet metal fabrication, and die casting, you can select the most appropriate method to ensure the success of your project.