Custom CNC Machining Service

- We offer cost-effective CNC machining solutions, from quick quoting to prototyping, mass production, strict quality assurance, and backed by all necessary certifications.

- Partner with us for your reliable, efficient, and high-precision CNC machining services.

- 20+ CNC Machines

- 100+ Metal & Plastic Materials

- Metal Parts Tolerance: ±0.005" (0.127mm) ~ ±0.0001" (0.0025mm)

- Plastic Parts Tolerance: ±0.01" (0.25mm) ~ ±0.001" (0.025mm)

- 1~7 days Rapid prototyping

- Variable Suface Finishes

- Low MOQ

1. Upload

Start by sending us your inquiry along with uploading your files or drawings. Include detailed requirements such as material specifications, quantity needed, and etc.

2. Comunication

Once we receive your inquiry, we'll review the files and requirements. Communicate with you promptly to clarify details, discuss feasibility, and provide initial feedback.

3. Prototyping

After finalizing the specifications and requirements, we'll proceed to create a prototype and send it to you. It allows you to see a physical sample of the product to verify the details.

4. Mass Production

If you verified the prototype, we will begin the mass production. Your order will be manufactured with precision and delivering high-quality products within the specified timeline.

From Concept to Production

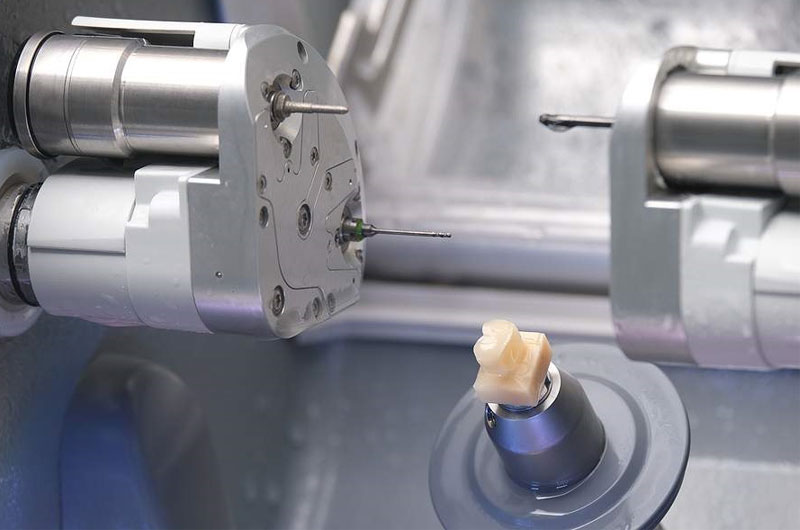

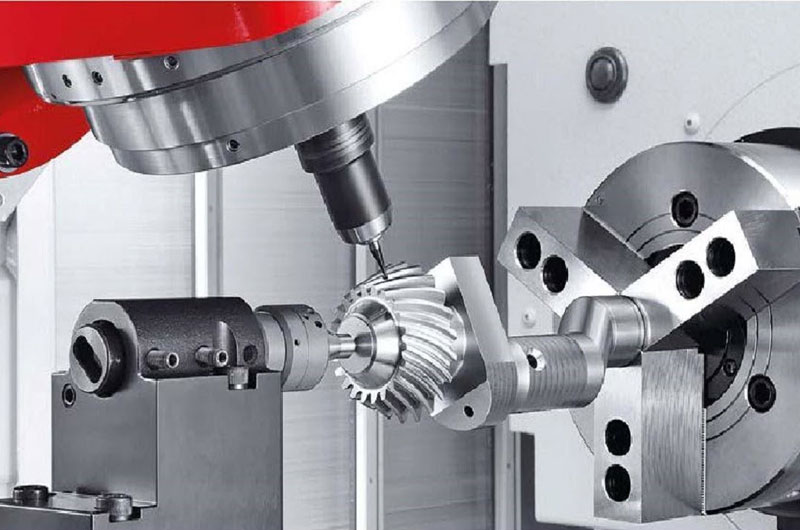

Our Available CNC Machining Types

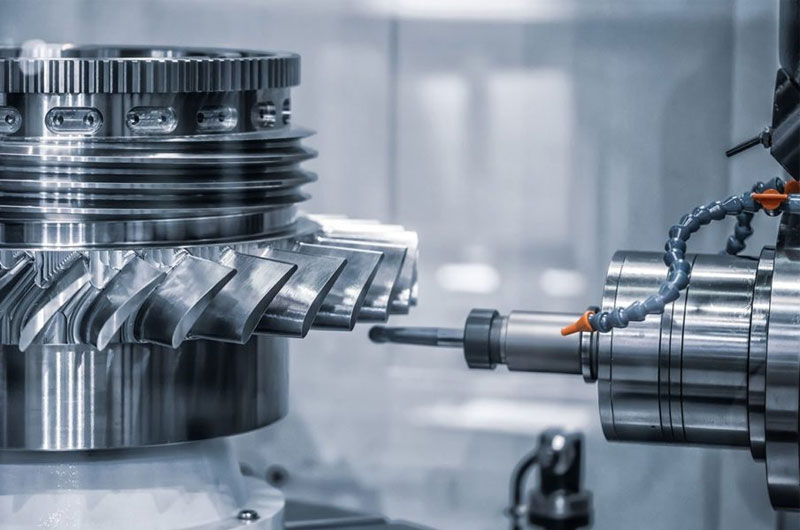

CNC Milling

- Use rotating multi-point cutting tools to remove material.

- 3-5 axis configuration.

- Suitable for metals, wood, foam.

- Versatile, capable of high precision and producing intricate parts, such as slots, holes, contours, and 3D surfaces.

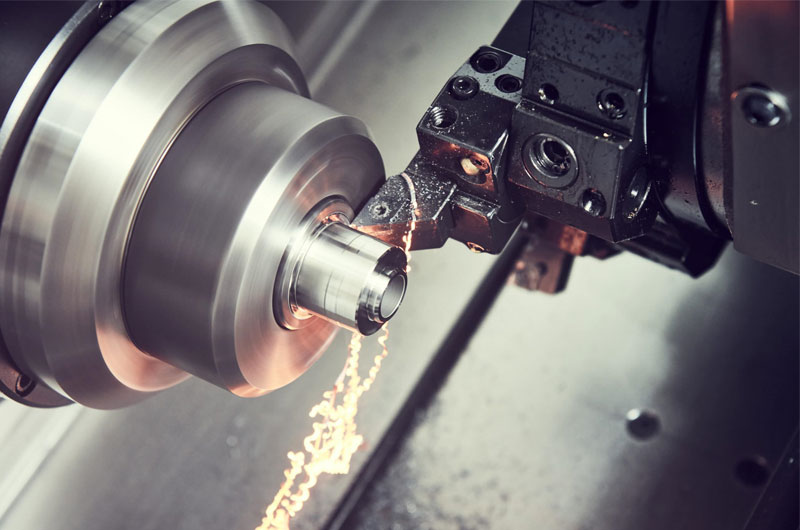

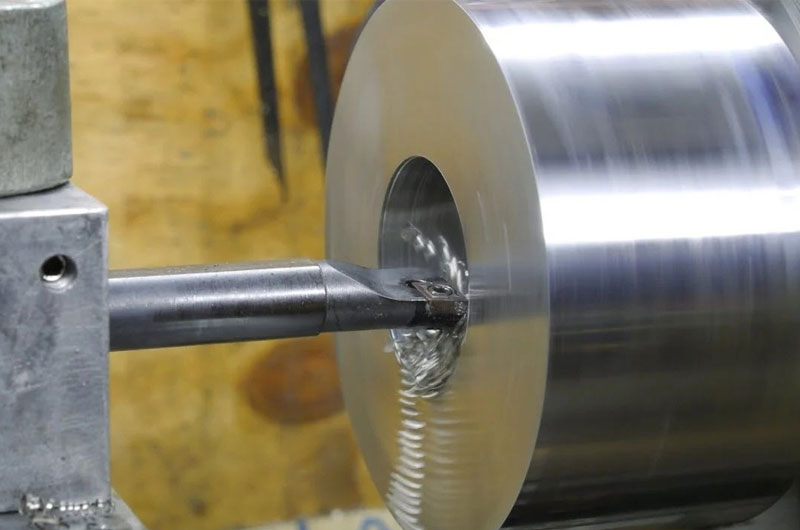

CNC Turning

- The workpiece rotates while a single-point cutting tool removes material.

- 2-5 axis configuration.

- Suitable for metals, wood, plastics.

- Excellent for producing symmetrical parts (e.g. shafts, bolts, nuts), high efficiency for high volume production.

CNC Drilling

- Uses a rotating drill bit to create holes in the workpiece.

- Multi spindle configuration.

- Suitable for metals, plastics, wood.

- Repeatable hole production with precision depth and diameter control, can be combined with other processes.

CNC Grinding

- Uses a rotating abrasive wheel to remove material.

- 2-6 axis configuration.

- Suitable for hard materials like metals, alloys, ceramics and plastics.

- Finishing surfaces, achieving high dimensional accuracy and surface quality.

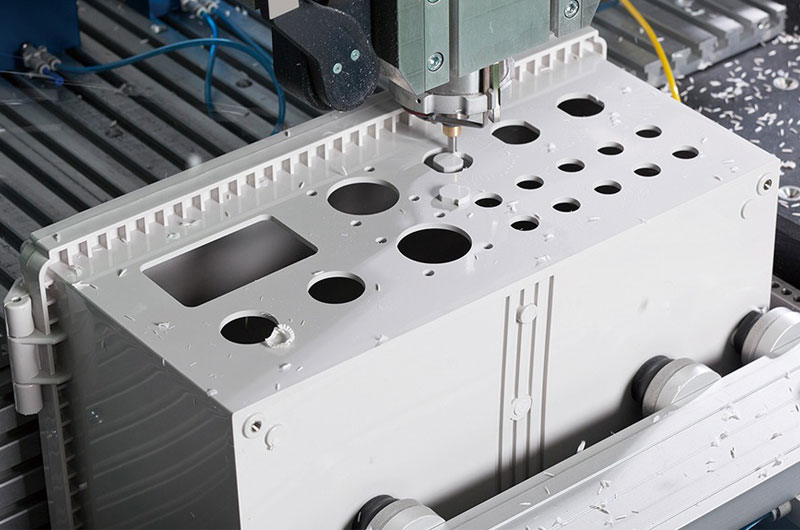

CNC Routing

- Uses a rotating cutting tool to cut, carve, and engrave non-metal materials.

- 3-5 axis configuration.

- Suitable for wood, plastics, soft metals and composite materials.

- High-speed machining ability, efficient for softer materials.

CNC Boring

- Enlarge a pre-existing hole using a single-point cutting tool.

- 3-5 axis configuration.

- Typically applied on metals.

- High precision, suitable for achieving smooth internal surfaces and tight tolerances in hole dimensions.

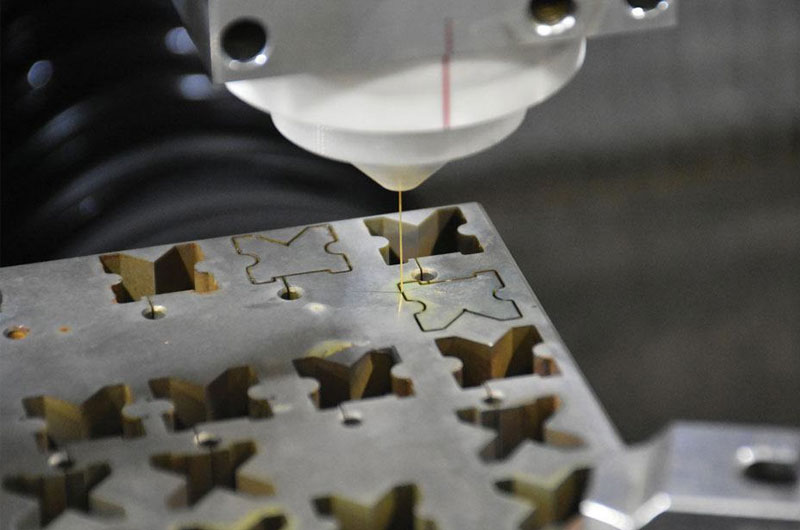

CNC EDM

- Uses electrical discharges (sparks) to remove material.

- 2-5 axis configuration.

- Suitable for hard or conductive materials.

- Non-contact process, minimal mechanical stresses on the workpiece, capable of complex geometries.

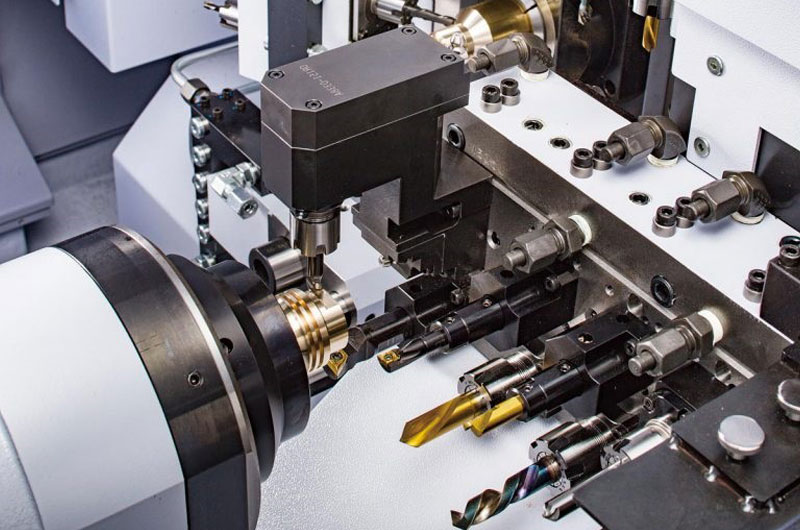

CNC Swiss Machining

- Rotates the workpiece and feeds it through a guide bushing for cutting.

- 5-8 axis configuration.

- Suitable for metals, plastics.

- Excellent for high precision small, complex parts for medical, aerospace, and electronics industries.

Materials For CNC Parts

Additionally, we also offer custom high-precision CNC machining services to align with your specific precision requirements.

Aluminum Alloy | Aluminum Alloy 6061 | Aluminum Alloy 5052 | Aluminum Alloy 2A12 | Aluminum Alloy 7075 | ||

Stainless Steel | Stainless Steel 301 | Stainless Steel 303 | Stainless Steel 304 | Stainless Steel 316 | Stainless Steel 316L | Stainless Steel 321 |

Stainless Steel 420 | Stainless Steel 430 | Stainless Steel 17-4PH | ||||

Alloy Steel | Q235 (A3 Steel) | 45 Steel | Cr12 | 3Cr13 | GCr15 | 40Cr |

Spring Steel 65Mn | Mold Steel SKD11 | |||||

Copper Alloy | Brass H59 | Brass H62 | Copper T2 | Oxygen-Free Copper TU2 | Tin Bronze QSn-6-6-3 | Beryllium Copper C17200 |

Other Alloys | Electrical Pure Iron DT4C | Electrical Pure Iron DT4E | Titanium Alloy TC4 | Magnesium Alloy AZ91D | ||

Plastics | ABS | PTFE | Delrin® POM | PMMA | PP | PPS |

PU | PVC | HDPE | LDPE | Nylon PA6 | Nylon PA66 | |

PC | PEEK | Phenolic Board | Epoxy Board FR4 | |||

Others | Carbon Fiber | Graphite |

Surface Finishes

As-Machined

- With no additional finishing operations. It shows visible tool marks .

- For metal & plastic machined parts.

- Surface Roughness: Ra 3.2 - 6.3 µm.

Bead Blasted

- A smooth, matte appearance by blasting with abrasive media.

- For metal, plastic and composite parts.

- Surface Roughness: Ra 1.6 - 3.2 µm.

Anodized

- Creating an oxide layer on the metal surface for a protective layer.

- Typically for aluminum parts.

- Surface Roughness: Ra 0.8 - 1.6 µm.

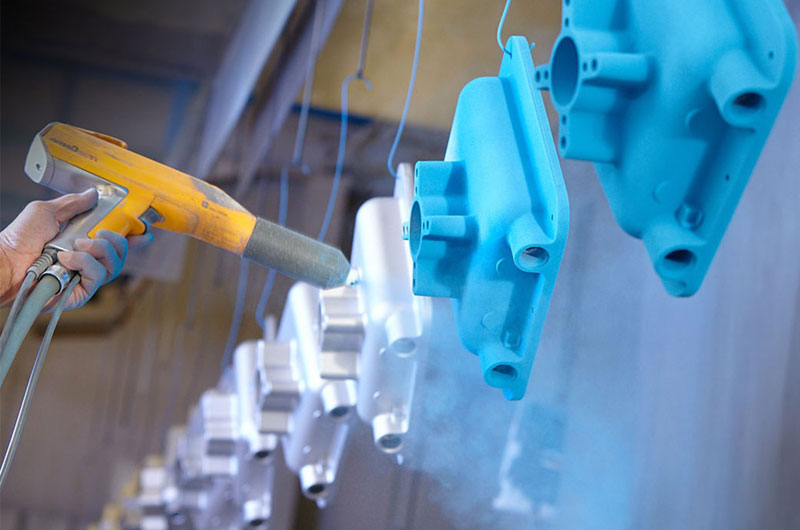

Powder Coated

- Applying powder to the surface, then cured under heat.

- For metal, plastic, MDF parts.

Brushed

- A unidirectional satin finish by brushing a fine abrasive over surface.

- Typically applied to metal parts.

- Surface Roughness: Ra 0.8 - 1.6 µm.

Polished

- Creates a highly mirror-like surface by using finer abrasives.

- Typically applied to metal parts.

- Surface Roughness: Ra 0.1 - 0.4 µm.

Electropolished

- An electrochemical process that removes a thin layer of the parts.

- For metal and alloy parts.

Chemical Film

- By immersing in or spraying the aluminum parts with the chemical film solution.

- For aluminum and its alloy parts.

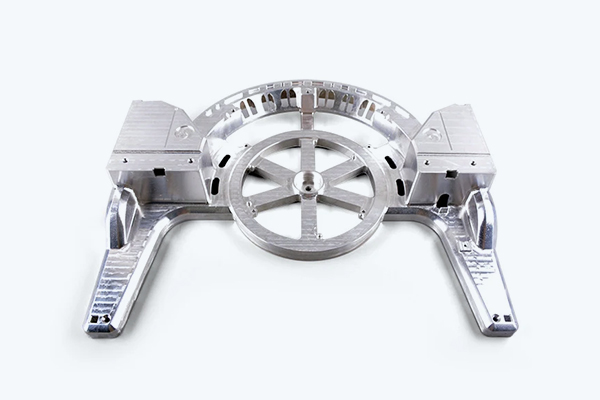

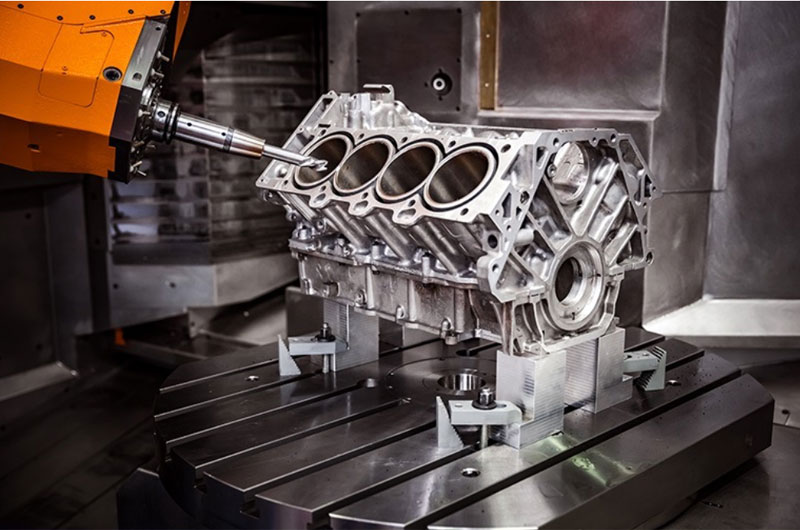

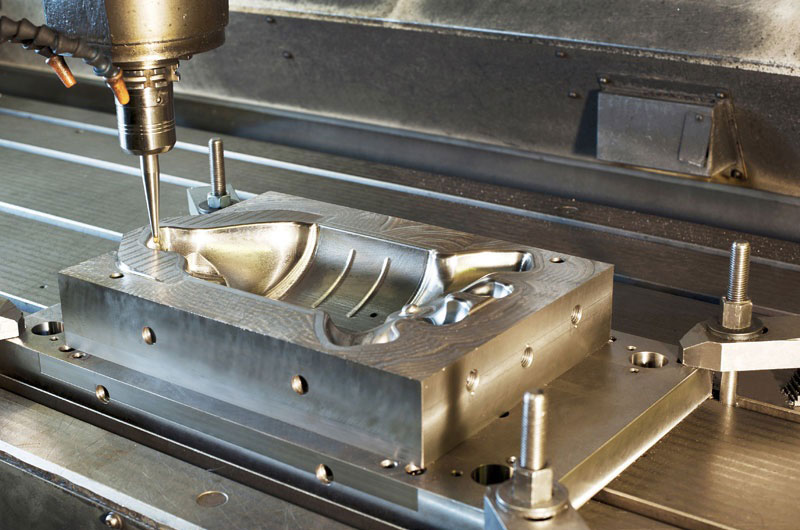

Our CNC Machining Projects

CNC Machining Applications

Aerospace

Automotive

Medical

Electronics

Produces precise enclosures, heatsinks, and connectors for electronics, ensuring optimal functionality and accuracy.

Industrial Machinery

Defense and Military

Tool and Die Making

Marine