CNC Grinding Service

- Our advanced CNC grinding capabilities ensure exceptional precision and surface finish for a variety of materials, including metals, alloys, ceramics and plastics.

- From fine finishes to precise tolerances, we are committed to providing top-notch grinding solutions that exceed industry standards.

- Various CNC Grinding Machines

- 2~6 Multi-Axis Configuration

- ±0.001" (0.025mm) Tolerance Achievable

- Precision Mesurment Tools (Micrometers & CMMs)

- Surface Finish Quality (Ra 0.1 to 1.6 µm)

- Suitable for metals, alloys, ceramics and plastics.

Our General CNC Grinders

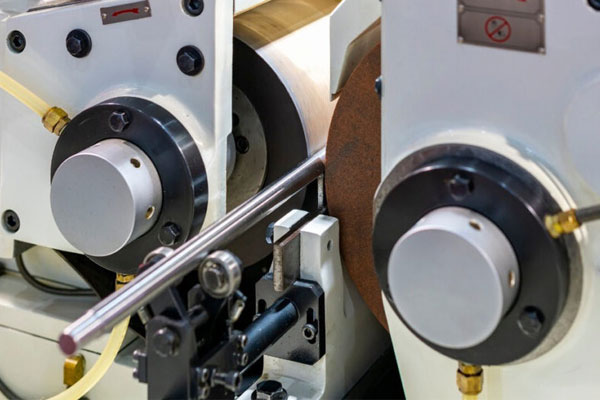

Tool & Cutter Grinder

- Primarily used to sharpen and recondition cutting tools such as drills, end mills.

- Multi-axis and multiple grinding wheels for handling intricate tool profiles.

- High precision, grind complex shapes, and adaptability to various tool types.

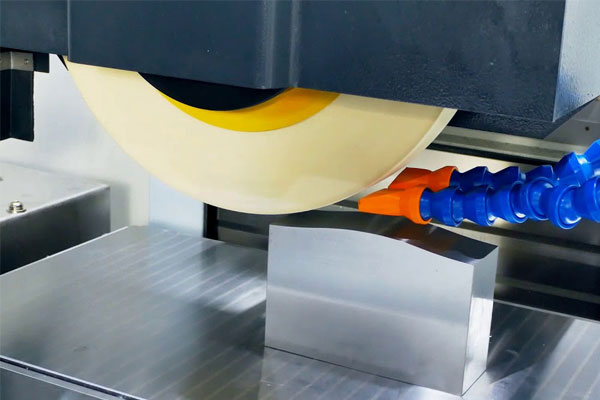

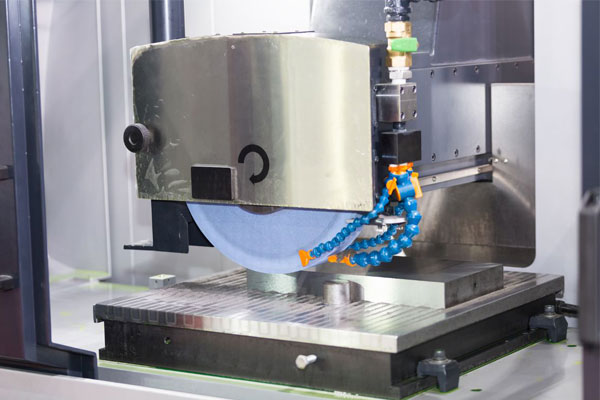

Surface Grinder

- Used for grinding flat surfaces on workpieces to achieve a smooth finish.

- Can work on a variety of materials, allowing for angled or contoured surfaces.

- Ideal for precision parts that require flatness, such as plates, molds, and dies.

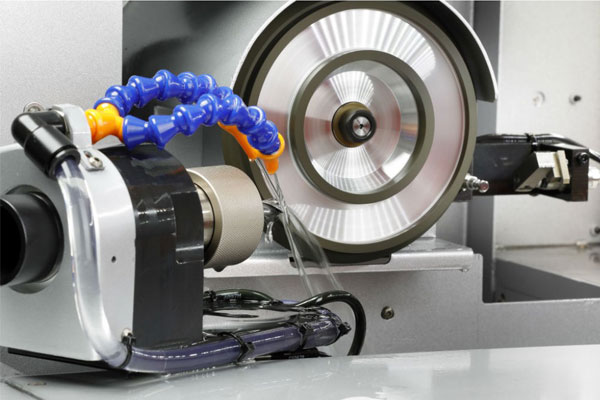

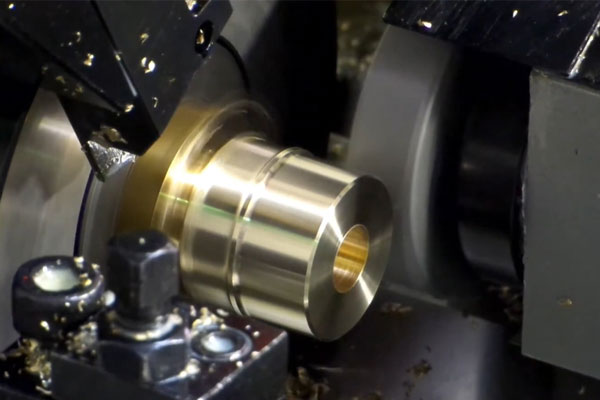

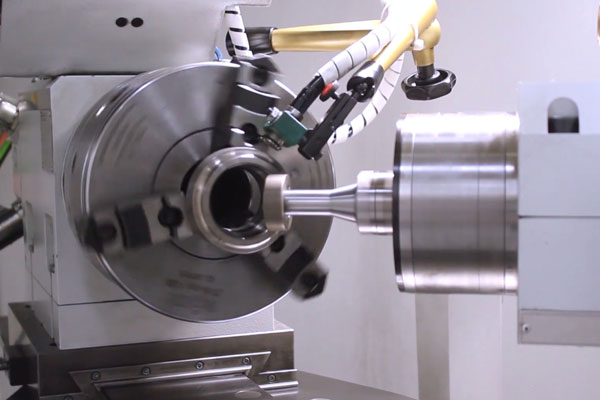

Cylindrical Grinder

- Used for grinding cylindrical surfaces, both external (OD) and internal (ID).

- Provides high precision in roundness and diameter of cylindrical parts.

- Manufacturing shafts and other cylindrical parts in automotive and machinery.

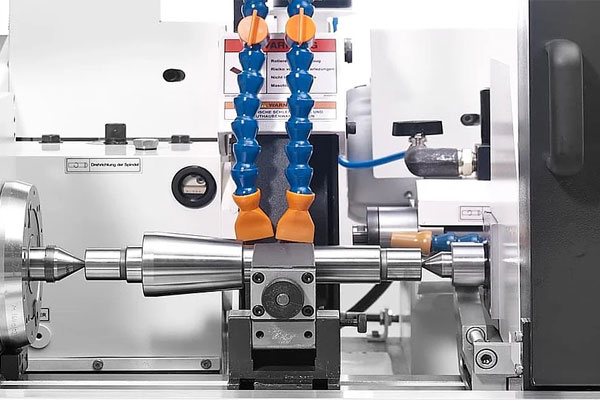

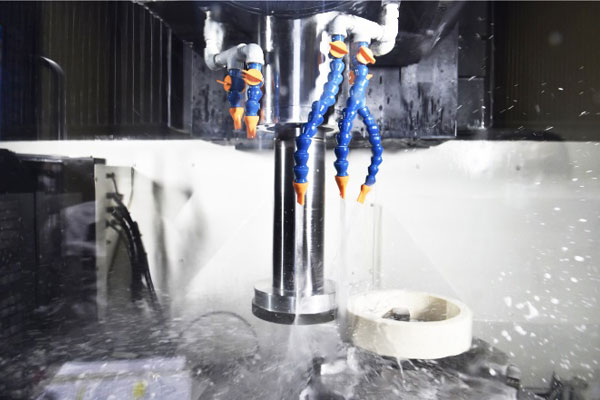

Centerless Grinder

- Grind the external surface of cylindrical parts without the need for a central axis to hold.

- Capable of high throughput and precision for mass grinding long cylindrical parts.

- For fabricating automotive and aerospace precision components (pins, dowels, rollers).

For Specific Purpose

Each of our CNC grinding machine is optimized for the specific workpieces and precision requirements of the components they are designed to grind, ensuring optimal performance in their respective applications.

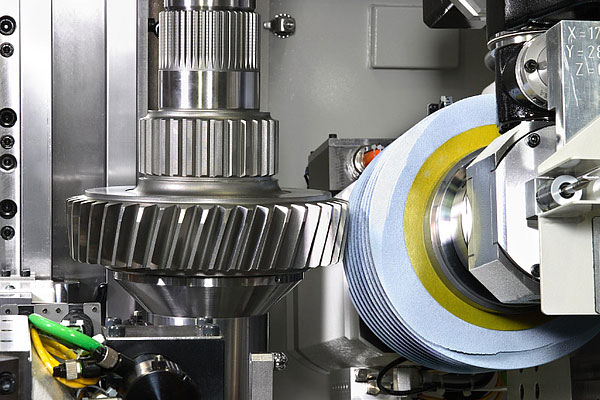

Gear Grinder

- Precise grinding of gear teeth, ensuring they mesh properly in mechanical systems.

- Can handles various gear types (spur, helical, bevel, etc) with high precision.

- Used in manufacturing gears for automotive, aerospace, and machinery industries.

Thread Grinder

- Can produce both internal and external threads with high accuracy.

- Grinding to exact thread standards such as ACME, metric, or trapezoidal.

- Capable of grinding a wide range of thread types (V-threads, worm threads, ball screws).

Crankshaft Grinder

- Specialized for grinding the main and rod bearings of crankshafts in engines.

- Can high precision grinding crankshaft journals, radii, and fillets.

- Ensures concentricity and roundness of journals, critical for engine performance.

Camshaft Grinder

- Use CNC to precisely shape the cam lobes, ensuring consistent valve timing.

- Supports grinding of various camshaft materials, like steel, cast iron, and aluminum.

- Used primarily in the automotive industry to manufacture camshafts for engines.

Materials for CNC Grinding

Aluminum

Aluminum is prone to clogging grinding wheels due to its softness, for grinding aluminum parts, we typically uses wheels with a coarse grit and coolants to avoid clogging and heat buildup.

Stainless Steel

Stainless steel has a higher strength, so we use a slower feed rate and harder grinding wheels, like aluminum oxide or CBN (cubic boron nitride), often with a coolant to reduce heat.

Brass

Brass is a softer metal, and easier to grind than SSL but still requires careful handling to avoid deformation and clogging. Use a medium to fine-grit wheel, with moderate pressure.

Ceramic

Ceramics are hard, brittle, and wear-resistant, with excellent thermal stability. Commonly, we use diamond or CBN wheels to grind at low speeds and coolant to cracks or chips.

Our CNC Grinded Workpieces

Shafts

Enhances the shaft’s concentricity, surface finish, and dimensional accuracy, catering to various mechanical needs.

Bearings

Bearings have precise dimensions and surface finishes, and reduce wear, leading to improved performance and longevity.

Gears

Gear teeth are uniformly finished and meet exact specifications, providing smooth and efficient engagement.