CNC Drilling Service

- Our drilling centers are equipped with many drill bit options and multiple spindles, enabling us to cater to various customer needs, from deep precision drilling to large-scale component processing.

- Our capabilities extend to drilling plates and tube workpieces made from metals, wood, and plastics.

- Multi-Spindle Drilling

- Various Drilling Bits Options

- Deep Hole Drilling Ability (100 Time the Hole's Diameter)

- Suitable for Metal, Wood and Plastics

Our Drilling Abilities

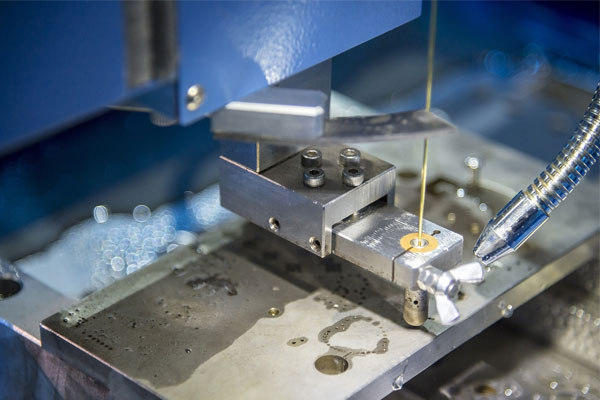

EDM Drilling

- Utilizes electrical discharges (sparks) to erode material and create holes.

- Perfect for drilling small, intricate holes in hard or exotic materials.

- Widely used for creating holes in carbide, hardened steel, and other tough materials.

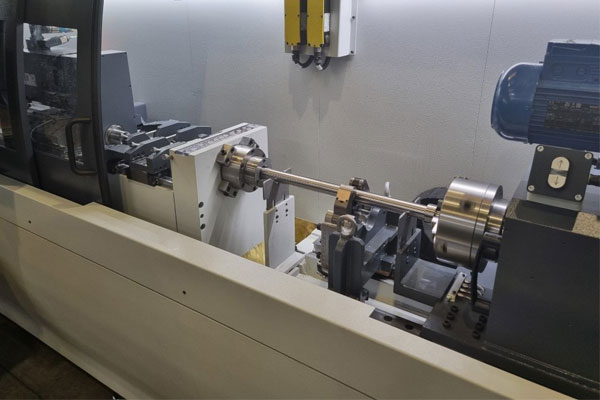

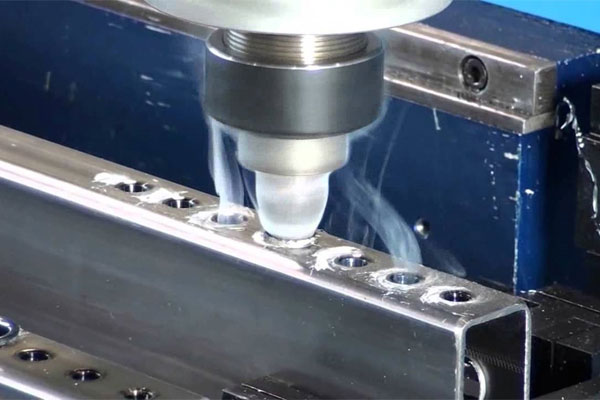

Gun Drilling

- A deep hole drilling technique for precision holes with a high length-to-diameter ratio.

- Uses a specialized gun drill bit for effective coolant delivery, and chip evacuation.

- Ideal for drilling deep, straight holes in materials like steel, aluminum, and titanium.

Dowel Drilling

- Create precise, straight holes for dowels for joining two components together.

- Ensures accurate tight fits for dowels, contributing to the structural integrity.

- Typically used in woodworking, joinery, cabinetry and furniture manufacturing.

Gantry Drilling

- Utilizes a gantry system where the drilling head moves along the gantry frame.

- The gantry design allows for multiple repeat drilling operations across large surfaces.

- Suitable for drilling large plates in industries like aerospace or shipbuilding.

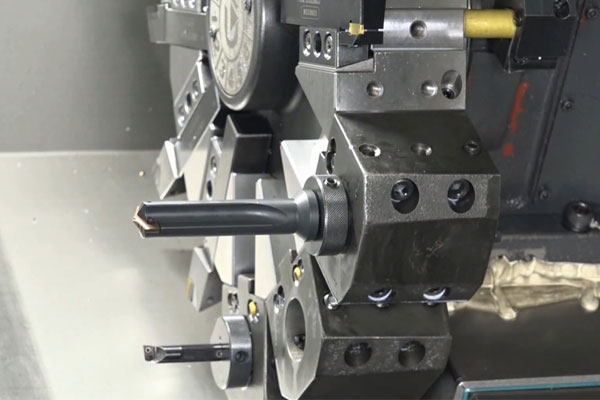

Peck Drilling

- Drill deep holes by breaking up the drilling process into small, incremental steps.

- Better chip removal and reduces heat buildup, avoid tool damage and improve hole quality.

- Useful for drilling holes in materials that are prone to chip binding or heat generation.

Pillar Drilling

- Involves a vertical drilling machine where the drill head is mounted on a pillar or column.

- Allows for drilling operations on various workpieces with a focus on vertical precision.

- It's commonly used for medium-sized parts and repetitive drilling tasks.

Spade Drilling

- Utilizes a spade drill bit, which is flat and has cutting edges at the tip.

- High speed and efficiency for larger holes, often with a more economical setup.

- Ideal for creating large holes in softer materials like wood, plastic, or aluminum.

Spot Drilling

- Creates a small indent or "spot" to guide subsequent drilling operations.

- Ensures accurate bit positioning and prevents wandering during subsequent drilling.

- Commonly used in metalworking and other precision machining operations.

Materials for CNC Drilling

CNC drilling can be performed on metals (steel, aluminum, titanium), plastics, and wood. Different materials can affect the choice of drill bits, feed rates, and coolant to ensure optimal performance and finish.

Steel

- High-speed steel (HSS), carbide or cobalt drill bits are commonly used for drilling steel.

- Lower spindle speeds and higher feed rates are typically used to prevent overheating.

- Coolant or cutting fluid is often necessary to reduce heat, lubricate the drill bit, and prolong tool life.

Wood

- Standard wood drill bits, Forstner bits, brad point bits, or spade bits are commonly used.

- Higher spindle speeds and lower feed rates are used for wood to achieve clean, splinter-free holes.

- Typically, no coolant is needed when drilling wood, as heat buildup is less of an issue.

Plastics

- Sharp, HHS or carbide drill bits are often used, sometimes with special coatings to reduce friction.

- Moderate spindle speeds and feed rates are used to prevent melting or cracking of the plastic.

- Compressed air or light coolant sprays can be used to reduce heat buildup, especially in harder plastics.

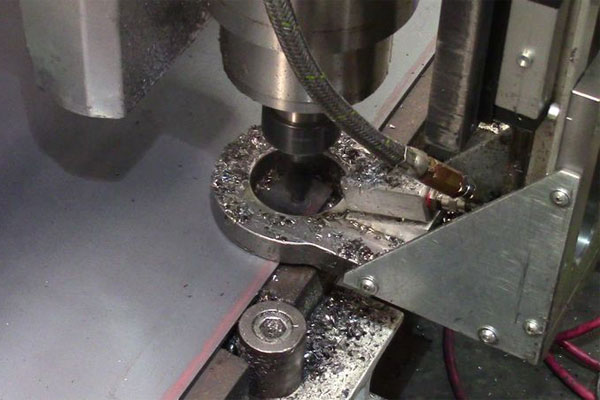

Our CNC Drilled Workpieces

PCB

CNC drilling is used to create precise holes for electronic components and vias. The accuracy ensures that components fit perfectly and electrical connections are reliable.

Plate

Plates, which can be made from various metals or plastics, are drilled for mounting holes. CNC drilling provides consistent and precise hole sizes and locations.

Tube

Tubes may be drilled for adding mounting holes, fittings, or to create access points. CNC drilling ensures accurate hole placement in cylindrical shapes.