CNC machining is a manufacturing process that uses computerized controls to operate machine tools. It can perform milling, turning, drilling, grinding, routing, boring, and cutting operations with remarkable precision.

The process starts with a digital design made in Computer-Aided Design (CAD) software, which is converted into a machine-readable format through Computer-Aided Manufacturing (CAM) software. The CNC machine then follows this program to manipulate tools and materials accurately, enabling the production of intricate parts and components.

1. Importance in Manufacturing

In today’s fast-paced industrial environment, manufacturers face increasing pressure to produce high-quality, customized products while minimizing lead times and costs.

CNC machining meets these demands by allowing for rapid prototyping and mass production with minimal waste.

As businesses strive for innovation and competitiveness, CNC machining stands out as a crucial process that enhances productivity and product quality.

2. Types of CNC Machining

CNC machining encompasses several processes, each with unique characteristics, advantages, and ideal applications. Here’s an in-depth look at the most common types of CNC machining:

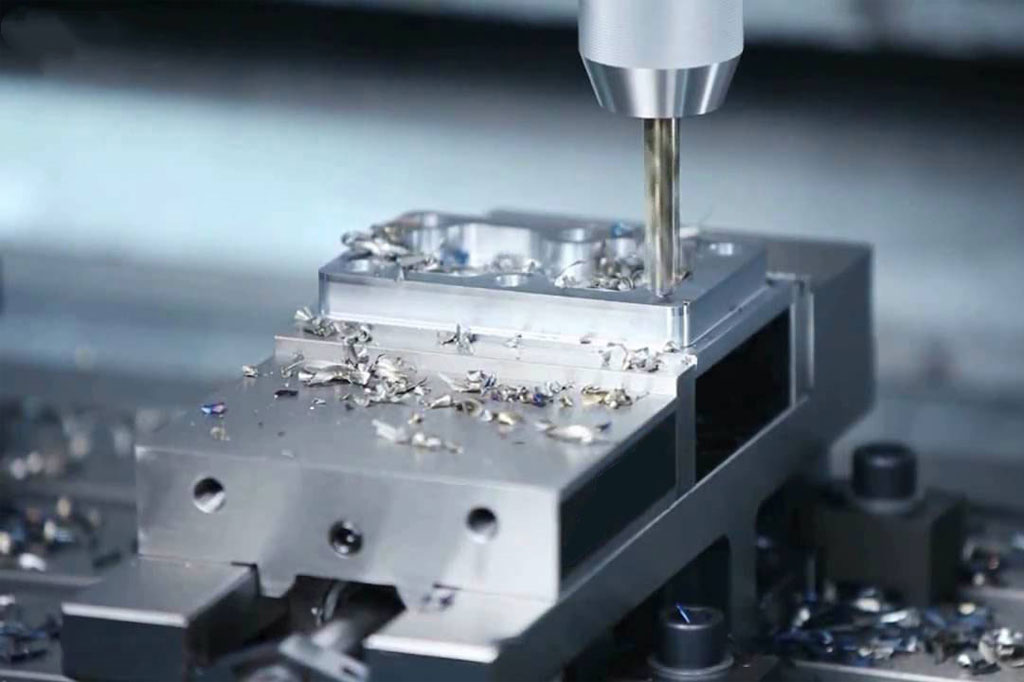

2.1 CNC Milling

The CNC milling is operated on multiple axes, typically 3, 4, or 5 axes, allowing for intricate shapes and complex designs.

The workpiece is secured to a table, and the cutting tool moves along various paths to create the desired form.

The operation can be vertical or horizontal, depending on the setup.

It is ideal for producing complex parts such as housings, brackets, and custom components, especially in industries requiring high precision.

Pros | Cons |

|

|

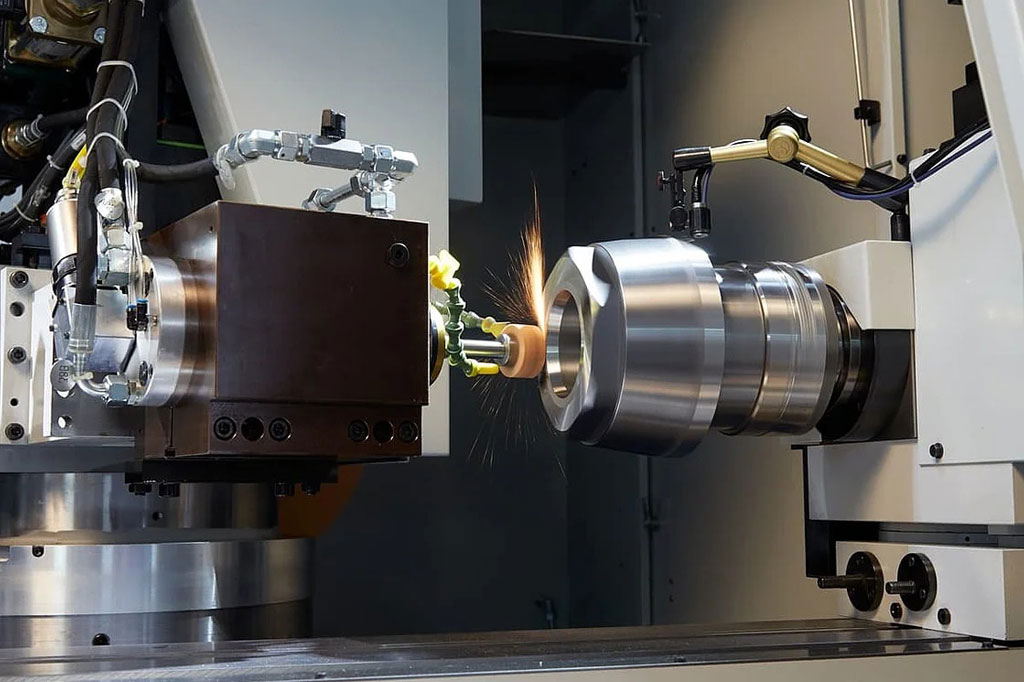

2.2 CNC Turning

CNC turning involves rotating a workpiece against a stationary cutting tool. This process is mainly used to create cylindrical parts through precise linear cutting.

The CNC lathe is programmed to precisely control parameters like rotation speed, feed rate, and depth of cut.

It is commonly applied to produce shafts, bushings, and fittings in automotive and industrial machinery.

Pros | Cons |

|

|

2.3 CNC Drilling

CNC drilling utilizes high-speed rotating drill bits to create deep holes in the workpiece.

The machine can automatically position the drill to produce holes at various locations and depths, depending on the design.

It is ideal for creating holes in plates, frames, and structural components, especially in construction and manufacturing.

Pros | Cons |

|

|

2.4 CNC Grinding

CNC grinding employs a rotating grinding wheel to remove material from a workpiece, achieving desired dimensions and surface finishes.

This process is crucial for finishing operations, especially on hard materials.

It is best used for precision parts, gears, and components requiring fine finishes, often in automotive and aerospace applications.

Pros | Cons |

|

|

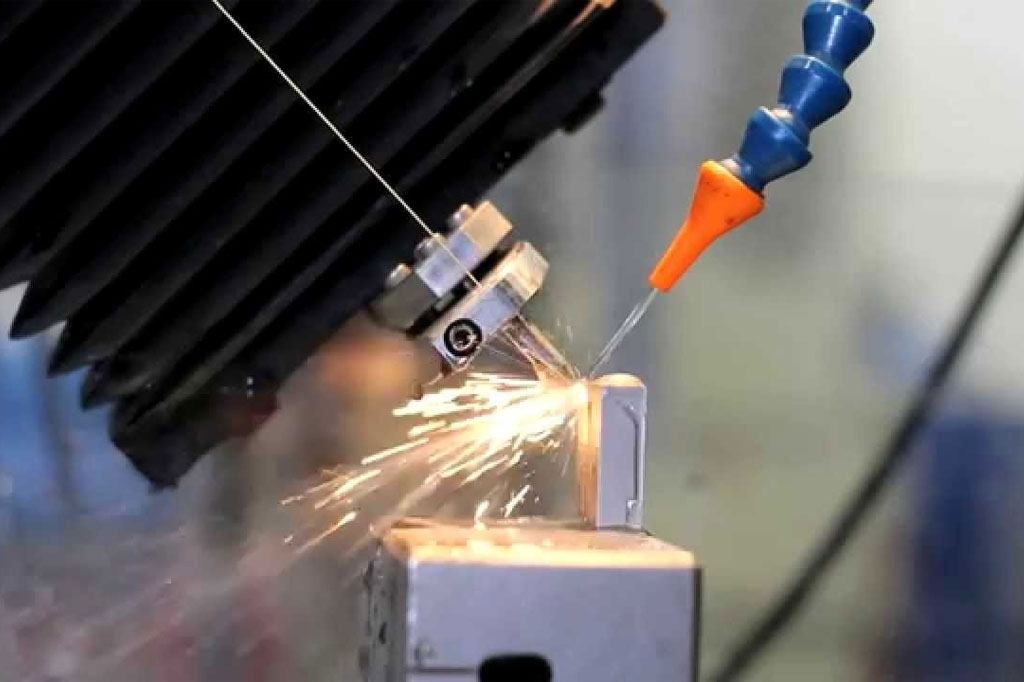

2.5 CNC Electrical Discharge Machining (EDM)

CNC EDM erodes and removes material from a workpiece using electrical discharges between an electrode and the workpiece.

This method is effective for processing hard materials and intricate shapes that other machining methods may struggle with.

It is commonly used in mold making, die sinking, and producing intricate parts in the aerospace and medical industries.

Pros | Cons |

|

|

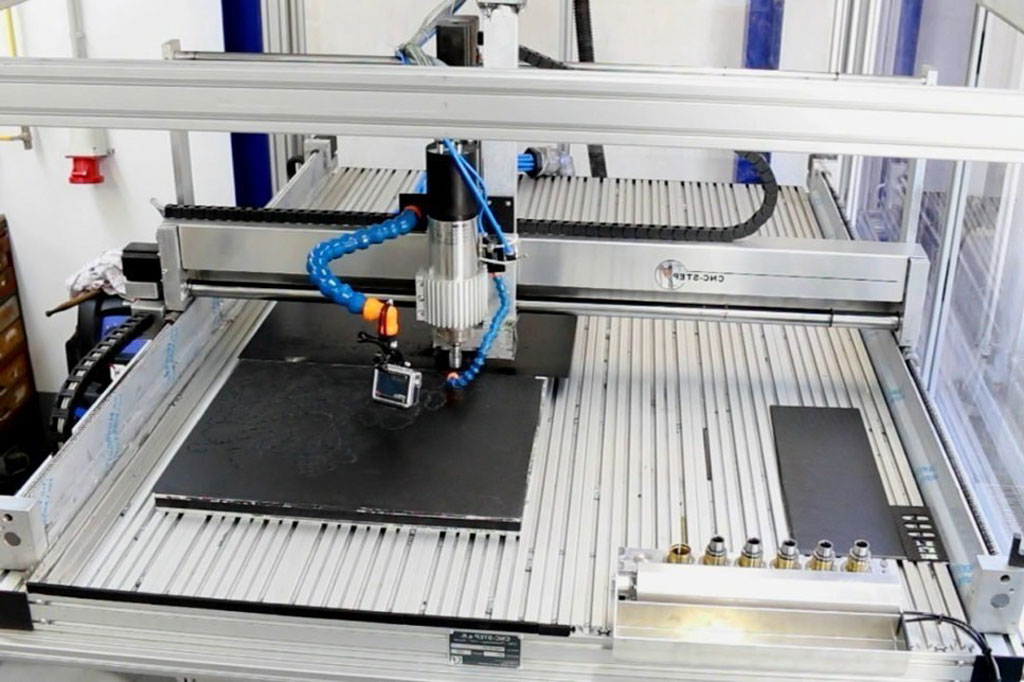

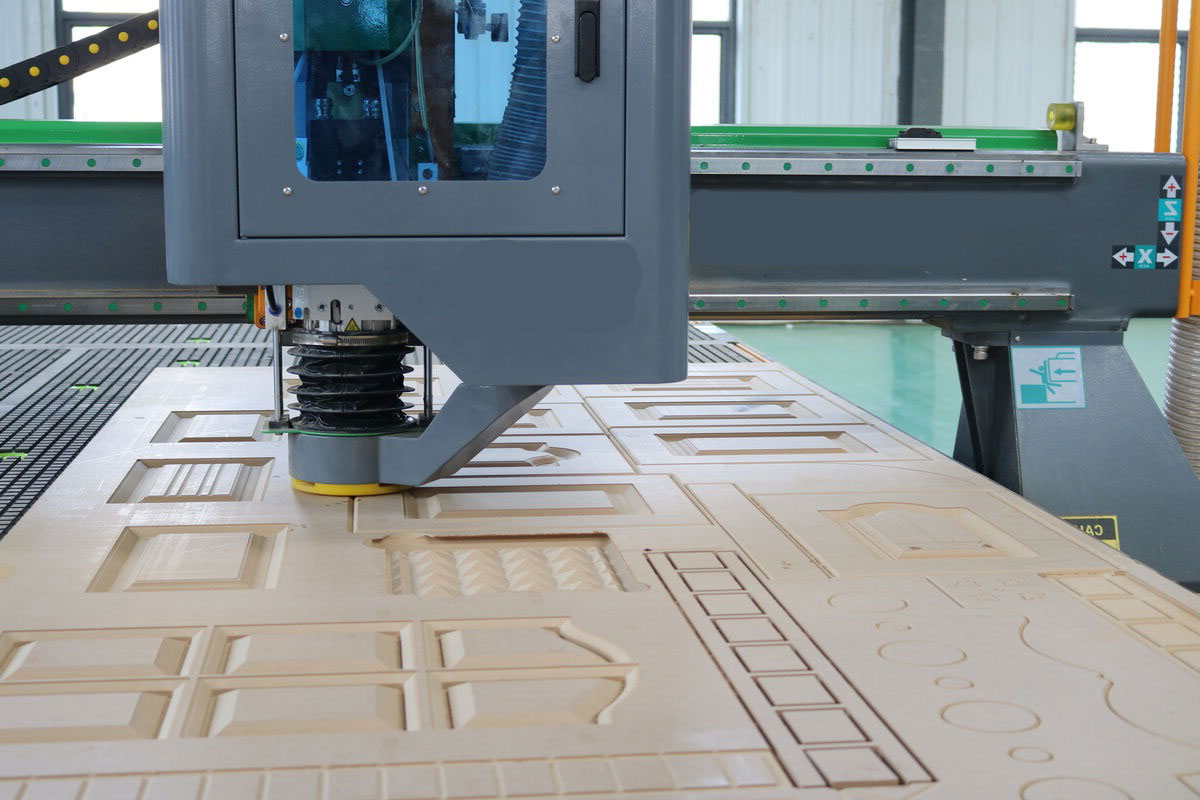

2.6 CNC Routing

CNC routing is a machining process that uses a rotating bit to cut through materials, primarily for larger sheets. It is similar to CNC milling but typically operates at higher speeds.

It is ideal for producing signage, furniture, and architectural components, often in woodworking and plastic industries.

Pros | Cons |

|

|

2.7 CNC Boring

CNC boring machines enlarge pre-existing holes with precision. This process ensures that holes are of the correct diameter and finish.

It is used for components requiring precise hole enlargements, such as in engine blocks and housings.

Pros | Cons |

|

|

2.8 CNC Swiss Machining

Swiss machining is a type of CNC turning where the workpiece is held in place while a sliding headstock moves the tool along the workpiece.

This technique allows for the simultaneous machining of multiple features, enhancing efficiency.

Its best use cases include medical device manufacturing, watchmaking, and any application requiring high precision in small components.

Pros | Cons |

|

|

3. Comparison Chart of CNC Machining Types

CNC Type | Best For | Precision | Speed | Material Types |

CNC Milling | Complex shapes | High | Moderate | Metals, plastics, composites |

CNC Turning | Cylindrical parts | High | High | Metals |

CNC Drilling | Creating holes | Moderate | High | Metals, plastics |

CNC Grinding | Precision finish | Very High | Low | Hard metals |

CNC EDM | Complex shapes | Very High | Low | Hard metals |

CNC Routing | Large flat components | Moderate | High | Wood, plastics |

CNC Boring | Enlarging holes | High | Low | Metals |

CNC Swiss | Small, intricate parts | Very High | Moderate | Metals |

4. Materials Used in CNC Machining

4.1 Metals

- Aluminum: Known for its lightweight and corrosion resistance, aluminum is widely used in various applications, from aerospace to consumer electronics. CNC machining allows for precise shaping of aluminum components, making it a favorite for prototypes and production runs.

- Steel: A versatile material with high strength and durability, steel is commonly machined for parts that require resilience. It’s used in construction, automotive, and machinery manufacturing, where strength is a priority.

- Stainless Steel: With excellent corrosion resistance, stainless steel is widely used in industries like food processing, pharmaceuticals, and medical equipment. CNC machining ensures that complex shapes and sizes meet stringent industry standards.

4.2 Plastics

CNC machining is not limited to metals; it also encompasses a wide range of plastics. Materials such as PTFE, acrylic, polycarbonate, and nylon are commonly machined for components in various applications, from consumer products to industrial parts, offering versatility and lightweight solutions.

- PTFE: CNC machining for PTFE offers precise, high-quality fabrication of this durable, non-stick material, ideal for components requiring excellent chemical resistance, low friction, and high-temperature tolerance.

- Acrylic: Known for its clarity and durability, acrylic is often used in displays, signage, and optical applications. CNC machining allows for precise cuts and finishes, enhancing its visual appeal.

- Polycarbonate: A tough, impact-resistant material, polycarbonate is used in safety glasses, electronic housings, and protective equipment. CNC machining can produce complex shapes and configurations.

- Nylon: Known for its excellent wear resistance and strength, nylon is commonly used in gears, bearings, and automotive parts. CNC machining can achieve precise dimensions and smooth finishes, making it suitable for functional components.

4.3 Composites

Composites, including carbon fiber and fiberglass, are increasingly popular in high-performance applications, such as aerospace and automotive industries.

CNC machining enables the precise shaping and finishing of composite materials, allowing manufacturers to produce lightweight yet durable components that improve overall performance.

4.4 Wood

Wood is also a common material for CNC machining, particularly in furniture making, cabinetry, and decorative elements. CNC routing is extensively used to cut, engrave, and shape wood with precise cuts and intricate designs. The flexibility of CNC technology allows for intricate designs and custom woodworking projects.

5. Precision and Tolerance

High precision minimizes the need for rework and reduces material waste, significantly improving overall production efficiency.

In CNC machining, tighter tolerances require more sophisticated equipment and longer machining times, often leading to increased production costs.

Manufacturers must balance the desired precision with economic considerations, selecting the right machining processes and tools to meet both quality and budgetary constraints.

Common Tolerance Standards:

- ISO 2768: A general tolerance standard used in engineering drawings for linear dimensions and angular dimensions.

- ASME Y14.5: A geometric dimensioning and tolerancing standard that defines a system for specifying and interpreting tolerances in engineering drawings.

6. Future Trends in CNC Machining

- Automation and Robotics: They can assist in loading materials, monitoring processes, and performing quality checks, thus streamlining operations.

- Advanced Materials: Composites and high-strength alloys present unique challenges and opportunities for CNC machining. Manufacturers are adapting their processes and equipment to handle these materials effectively, ensuring quality and performance while minimizing waste.

- Software Developments: Advancements in software, particularly CAD/CAM systems, are streamlining the design and machining processes. Modern software solutions enable better simulation, improved tool path optimization, and enhanced user interfaces, making it easier for operators to program and control CNC machines.

- Industry 4.0 Integration: Industry 4.0 technologies allow for remote monitoring of CNC machines, enabling manufacturers to track performance, diagnose issues, and perform maintenance proactively. This capability reduces the risk of unexpected failures and minimizes production disruptions.