Powder coating is a popular finishing technique that applies a dry powder to a metal surface and then cures it using heat.

Unlike traditional liquid paint, the powder coating process results in a durable, smooth finish that offers excellent protection against corrosion, scratches, and weathering.

However, not all metals are suitable for powder coating, as the metal’s properties can affect how well the coating adheres and performs over time.

Here’s a detailed look at metals that can and cannot be powder coated.

Metals That Can Be Powder Coated

1. Steel

Steel is one of the most common metals used for powder coating, thanks to its strength and durability. Whether it’s carbon steel, mild steel, or stainless steel, powder coating can improve the metal’s appearance and resistance to corrosion.

- Carbon Steel & Mild Steel: Carbon steel is widely utilized in the construction, automotive, and industrial sectors. Mild steel, a subset of carbon steel, is widely used for items like furniture, appliances, and architectural elements. Powder coating on these metals offers an extra layer of protection against moisture and rust, significantly enhancing their lifespan.

- Stainless Steel: Stainless steel is known for its resistance to corrosion, but powder coating can further enhance its aesthetic value and resistance to scratches and weather conditions. It’s commonly used in kitchen appliances, outdoor furniture, and structural components.

2. Aluminum

Aluminum is another popular metal for powder coating, primarily because of its light weight, strength, and natural resistance to rust. However, aluminum is still susceptible to scratches and dents, which can compromise its longevity. Powder coating creates a strong, uniform finish that adds durability while maintaining the metal’s lightweight properties.

Powder-coated aluminum is frequently chosen for automotive, aerospace, and architectural applications because of its durability and aesthetic qualities. Aluminum windows, doors, frames, and trim, as well as car rims and bicycle parts, often feature powder-coated finishes.

3. Zinc-Coated Metals (Galvanized Steel)

Galvanized steel, which is steel coated with a layer of zinc to prevent rust, can also be powder-coated, although special care is required. The zinc coating can sometimes interfere with the adhesion of the powder, so it’s important to use proper surface preparation methods.

For best results, galvanized steel should be pretreated (via processes like chromate conversion or mechanical abrasion) to ensure the powder coating adheres properly.

Galvanized steel is commonly used in construction, fences, and HVAC systems, and powder coating provides additional protection and aesthetic appeal.

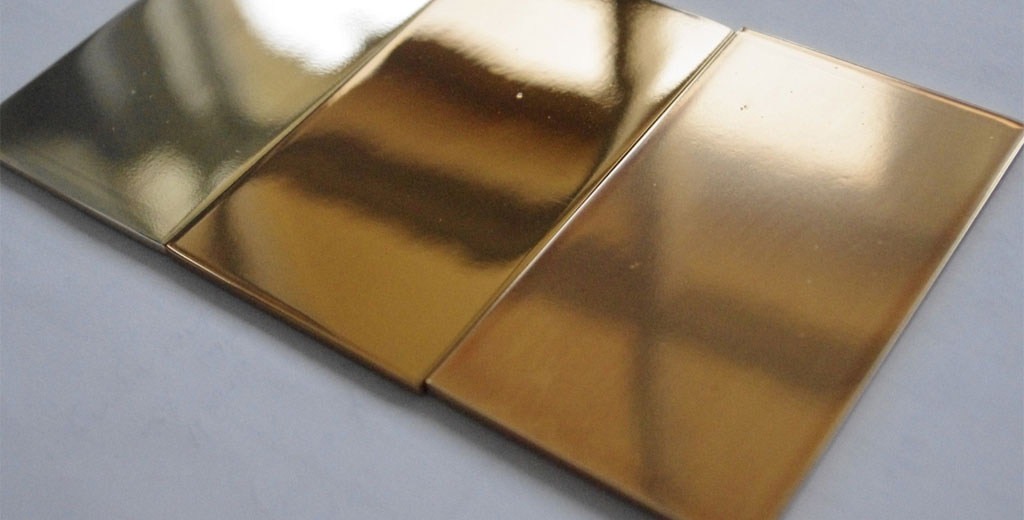

4. Copper and Brass

Although less common, copper and brass can also be powder-coated, though the process requires additional care. Both metals are celebrated for their excellent conductivity and visual appeal, particularly in decorative uses.

- Copper: Copper develops a patina over time, which can be desirable for some applications. Powder coating is often applied to maintain the metal’s appearance while offering protection against corrosion.

- Brass: Brass, a copper-zinc alloy, is often used for decorative items like handles, light fixtures, and architectural accents. Powder coating can enhance its beauty and provide protection from tarnishing.

5. Iron and Cast Iron

Both iron and cast iron can be powder-coated, with excellent results. These metals are often used for heavy-duty applications, such as outdoor furniture, garden fixtures, and industrial machinery. Iron is more susceptible to rusting compared to other metals, making powder coating an effective way to protect it.

Cast iron items like grates, tables, and heavy-duty machinery can benefit greatly from powder coating, as it helps extend their lifespan by providing an extra layer of protection against rust and environmental damage.

6. Titanium

Titanium is a lightweight, high-strength metal with inherent corrosion resistance, making it ideal for aerospace, medical, and advanced industrial applications. Although it has excellent properties, powder coating can further improve its aesthetics and protect against scratches.

Titanium can be powder-coated for cosmetic reasons, such as in watches, eyeglasses, or high-end bicycle components. Its resistance to corrosion makes titanium particularly well-suited for demanding environments, such as marine and chemical industries.

Metals That Cannot Be Powder Coated

While many metals are suitable for powder coating, there are also certain metals that do not work well with this process.

1. Lead

Lead is not recommended for powder coating because it has a soft, malleable nature that makes it prone to damage and poor adhesion. Additionally, lead is toxic, and its handling and disposal require special attention.

2. Magnesium

Magnesium has a highly reactive surface that makes it difficult to coat with powder. In some cases, magnesium may catch fire when exposed to high temperatures, so it is generally avoided in powder coating processes.