Welding is a critical process in manufacturing, construction, and repair, enabling the joining of various metals to create durable and functional components.

However, different metal welding requires understanding their unique properties and challenges.

In this article, we will explore considerations for welding 6 common metal materials, such as stainless steel, aluminum, cast iron, brass, copper, and titanium.

1. Considerations for Welding Stainless Steel

Types of Stainless Steel

Stainless steels are categorized into austenitic, ferritic, martensitic, duplex, and precipitation-hardening (PH) grades. Each type has distinct welding requirements. Austenitic stainless steels are the most weldable but prone to warping and sensitization. Ferritic stainless steels are prone to grain growth, which can compromise toughness.

Heat Input

Minimize heat input to prevent distortion and sensitization, which can reduce corrosion resistance. Use techniques such as pulsed TIG or MIG welding to control heat.

Filler Material Selection

To ensure compatibility and maintain corrosion resistance, match the filler material to the grade of the base metal. For dissimilar stainless steels, select a filler material compatible with both.

Shielding Gas

Use a mixture of argon and a small percentage of oxygen or helium for MIG welding. For TIG welding, pure argon is often sufficient.

Pre- and Post-Weld Treatment

Clean the surfaces thoroughly before welding to eliminate any contaminants. Post-weld passivation or pickling can restore corrosion resistance.

2. Considerations for Welding Aluminum

Oxide Layer

The oxide layer of aluminum has a higher melting point than the base metal. Use AC TIG welding or a dedicated cleaning step to remove this layer for better weld penetration.

Thermal Conductivity and Expansion

Aluminum’s high thermal conductivity causes rapid heat dissipation, requiring higher heat input. Additionally, its high thermal expansion can lead to warping.

Filler Material

Choose filler materials like 4043 or 5356 alloys based on the base metal’s composition and desired weld properties.

Shielding Gas

Argon is the primary shielding gas for aluminum welding. For thicker materials, an argon-helium mix may improve heat input.

Technique

TIG and MIG welding are the preferred methods. Use a push technique for MIG welding to ensure proper gas coverage and minimize contamination.

3. Considerations for Welding Cast Iron

Preheating

Preheat the cast iron to 500–700°F (260–370°C) to reduce thermal shock and minimize cracking.

Filler Material

Nickel-based fillers, such as Ni-Fe or pure nickel rods, are commonly used for cast iron to accommodate its brittleness.

Cooling Rate

Control the cooling rate to prevent stress and cracking. Slow cooling, often achieved by burying the workpiece in sand or insulating material, is crucial for preserving material properties.

Surface Preparation

Clean the surface thoroughly to remove oils, grease, and impurities that can affect weld quality.

Weld Technique

Employ short, controlled welds to reduce heat input and minimize the likelihood of cracking. Peening the weld immediately after each pass can relieve stress.

4. Considerations for Welding Brass

Zinc Vaporization

Zinc vaporizes at lower temperatures, which can lead to porosity and harmful fumes. Always weld in a well-ventilated space or use a fume extractor to ensure safety.

Filler Material

Use a filler rod compatible with the brass alloy. Silicon bronze rods are often used to achieve a strong weld.

Heat Input

Control heat input to minimize zinc loss and reduce the risk of cracking. Use low-heat techniques like TIG brazing instead of traditional welding when possible.

Shielding Gas

Argon is the preferred shielding gas for brass welding to prevent oxidation.

Post-Weld Cleaning

Clean the weld area thoroughly to remove oxides and residues.

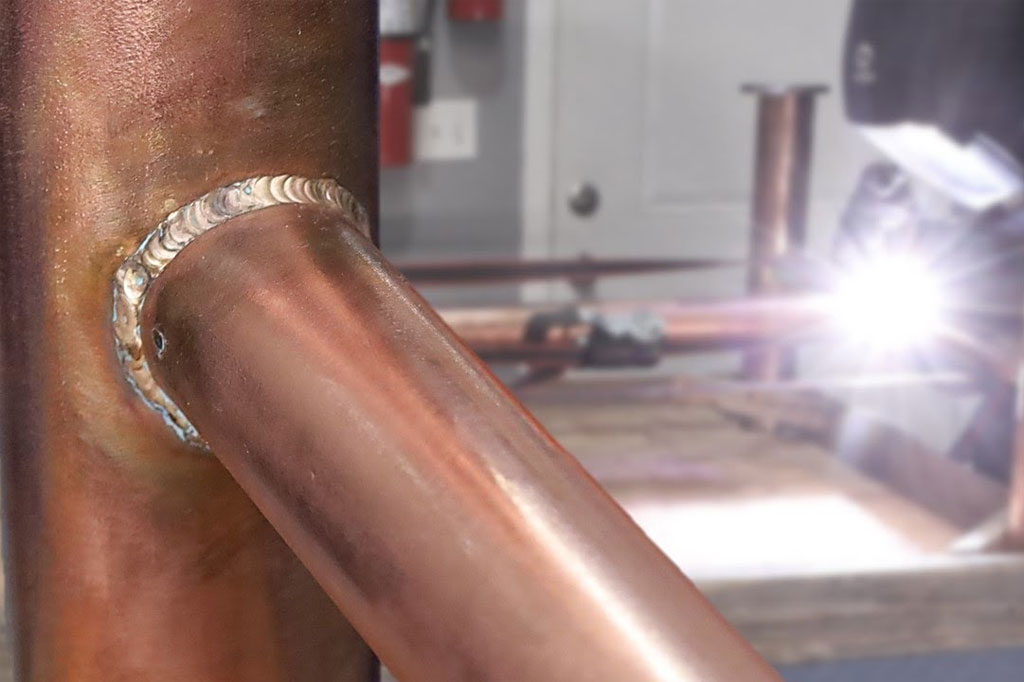

5. Considerations for Welding Copper

Thermal Conductivity

Copper’s high thermal conductivity requires high heat input and preheating for thick sections to ensure proper penetration.

Oxidation

Copper oxidizes easily at high temperatures. Use inert shielding gases like argon or argon-helium mixes to prevent oxidation.

Filler Material

Match the filler material to the base copper alloy. For pure copper, deoxidized copper filler rods are ideal.

Pre- and Post-Weld Treatment

Preheat the material to around 400–600°F (200–300°C) and cool slowly to prevent cracking.

Weld Techniques

Use TIG welding for precise control. For thicker sections, MIG welding or oxy-fuel welding may be more efficient.

6. Considerations for Welding Titanium

Shielding Atmosphere

Titanium reacts with oxygen, nitrogen, and hydrogen at high temperatures. Use an inert gas (pure argon or argon-helium mix) and ensure proper shielding, including back-purging.

Cleanliness

Clean the material thoroughly to remove contaminants. Even small amounts of oil or grease can lead to weld defects.

Heat Control

Minimize heat input to avoid embrittlement and discoloration. Use a low amperage setting and keep the weld area compact.

Filler Material

Use filler rods that match the base titanium alloy to maintain strength and corrosion resistance.

Welding Techniques

TIG welding is the preferred method for titanium due to its high precision and control. Use a trailing shield to ensure adequate coverage of the cooling weld.

Conclusion

Welding different metals requires a deep understanding of their physical and chemical properties, as well as tailored techniques to address unique challenges. By considering factors such as heat input, filler materials, shielding gases, and pre- and post-weld treatments, welders can achieve high-quality, durable welds across a variety of metals.