Welding is a fundamental process in manufacturing and fabrication industries, providing the ability to join metals and other materials with strength and precision.

The foundation of effective metal welding service lies not only in the skilled welders and welding techniques, but also in selecting the appropriate joint type, as each offers specific benefits and challenges depending on the application.

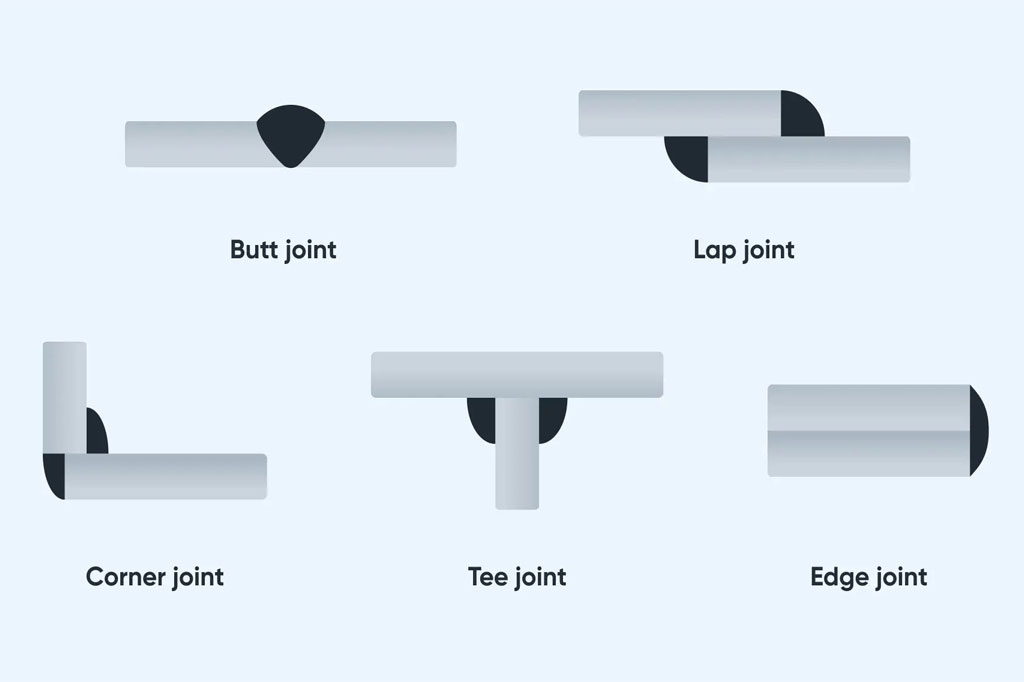

The five basic welding joint types include butt joint, lap joint, tee joint, corner joint, and edge joint.

In this article, we will delve into their characteristics, advantages, disadvantages, welding processes, and applications, followed by considerations for choosing the right joint type.

1. Butt Joint

The butt joint is the most widely utilized welding joint, consisting of two metal pieces aligned in the same plane and joined at their edges. Its simplicity makes it a popular choice for structural applications where components need to be connected in a flat or linear arrangement.

Butt Joint Advantages:

- Easy to set up and weld, making it cost-effective.

- Allows for strong, durable connections when properly welded.

- Minimal material overlap, leading to less waste.

Butt Joint Disadvantages:

- Requires precise edge preparation for strong welds.

- Lower strength to other joint types when subjected to certain loads.

Butt Joint Welding Process

Butt joints are commonly welded using techniques like MIG, TIG, or arc welding. Proper preparation of the edges is essential to ensure a strong weld. This often includes beveling the edges, especially for thicker materials, to allow the welding electrode to penetrate deeply into the joint.

Butt Joint Applications

Butt joints are used in the construction of pipelines, metal frames, automotive parts, and structural components like beams and columns. Their simplicity and versatility make them essential in various welding applications.

2. Lap Joint

A lap joint is created when two metal pieces overlap, forming a layered connection. This joint type is ideal for joining two pieces of metal of different thicknesses or for cases where a stronger, overlapping connection is needed.

Lap Joint Advantages:

- Allows for joining metals of different thicknesses.

- Offers a stronger bond due to the larger surface area of overlap.

Lap Joint Disadvantages:

- Prone to corrosion if not properly sealed, as gaps between layers can trap moisture.

- Increased material usage due to the overlap.

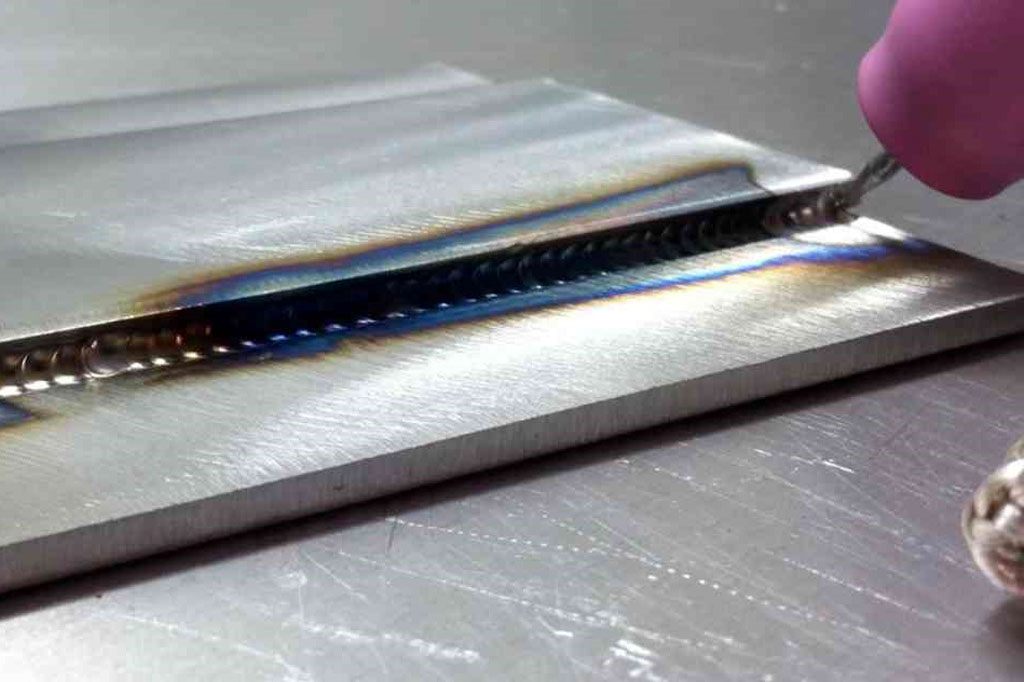

Lap Joint Welding Process

Lap joints can be welded using various methods, including spot welding, MIG welding, or TIG welding. The weld is typically applied along the edge of the overlapping metal, creating a strong bond between the two pieces. To minimize corrosion risk, welders often apply additional sealant or protective coatings.

Lap Joint Applications

They’re commonly used in sheet metal fabrication, automotive body panels, and applications requiring the joining of metals with different thicknesses. They are also commonly used in shipbuilding and aerospace applications.

3. Tee Joint

A tee joint is formed when two metal pieces meet at a right angle, creating a “T” shape. One piece of metal is placed perpendicular to the edge of the other, creating a joint that resembles the letter “T.”

Tee JointAdvantages:

- Provides strong support for load-bearing applications.

- Offers flexibility in terms of welding position and orientation.

Tee Joint Disadvantages:

- Prone to high levels of stress at the weld, which can cause cracking or failure over time.

- Precise alignment is crucial for achieving a strong weld.

Tee Joint Welding Process

Tee joints are typically welded using MIG, TIG, or arc welding. The weld is applied at the intersection of the two pieces, and in many cases, multiple passes may be required to achieve sufficient penetration and strength, especially for thicker materials.

Tee Joint Applications

Tee joints are commonly used in the construction of structural frames, metal furniture, and shipbuilding, as the Tee welded joint needs to support a vertical load.

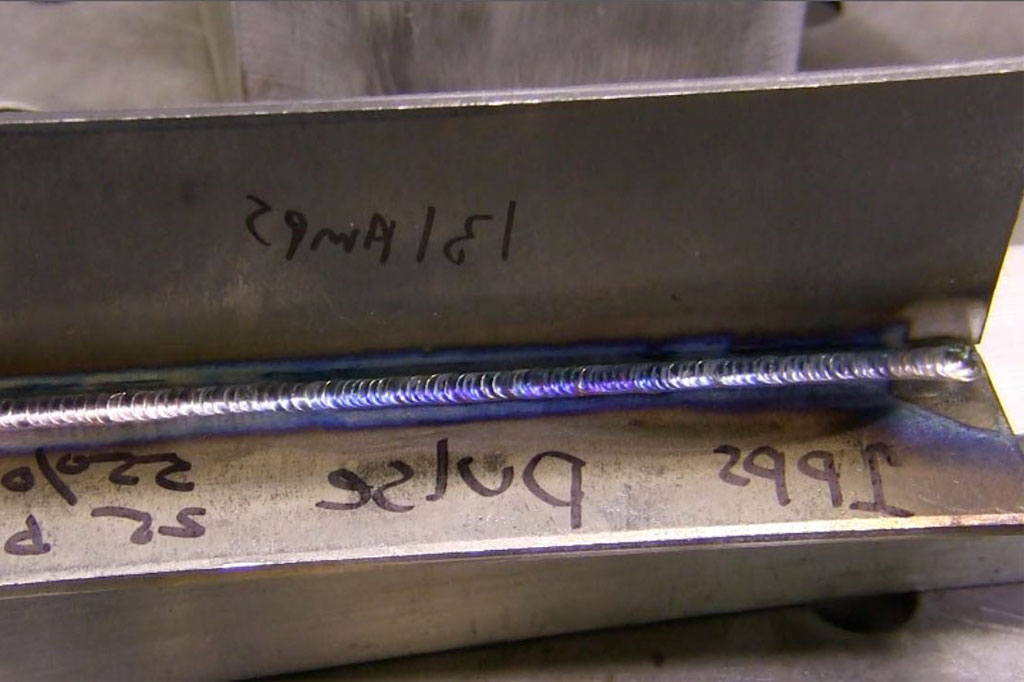

4. Corner Joint

The corner joint occurs when two metal pieces meet at a right angle, often at the edge or corner. This joint type is frequently used in frame construction and box-like structures.

Corner Joint Advantages:

- Suitable for creating enclosed or open boxes and frames.

- Provides good load distribution when properly welded.

Corner Joint Disadvantages:

- Can be prone to distortion or warping due to the heat of welding.

- Welding in the corner of a tee joint requires precision to ensure adequate strength.

Corner Joint Welding Process

Corner joints are usually welded using MIG, TIG, or arc welding. Full penetration welding is typically necessary to ensure the joint’s strength and durability due to the exposed edges. Preheating the metal may be necessary for thicker materials to prevent warping.

Corner Joint Applications

Corner joints are used in the fabrication of frames, enclosures, metal boxes, various architectural structures, cabinets, and other welded metal assemblies.

5. Edge Joint

Edge joints are created when the edges of two or more metal pieces are placed parallel to one another and welded together along the edge. This type of joint is typically used for thinner materials or in applications where the metals are not subject to significant stress.

Edge Joint Advantages:

- Suitable for thin materials where edge welding is required.

- Allows for minimal material usage.

Edge Joint Disadvantages:

- Not ideal for heavy-duty or high-stress applications.

- Limited strength compared to other joint types.

Edge Joint Welding Process

Edge joints are usually welded using MIG or TIG welding. The weld is applied along the aligned edges of the metal pieces, and in many cases, the weld must penetrate deeply to create a secure bond.

Edge Joint Applications

Edge joints are used in sheet metal fabrication, especially in applications like manufacturing heat exchangers, light metal frames, and other thin-walled structures. They are also used in the production of metal enclosures and cabinets.

Welding Considerations for Joint Types

Several factors must be considered when choosing a welding joint type for a project:

- Material Thickness: Some joints, like the butt and lap joints, are better suited for thicker materials, while edge joints are ideal for thinner metals.

- Stress Distribution: Tee and corner joints can handle higher loads but must be welded carefully to avoid stress concentration.

- Welding Position: Different joint types require specific welding positions (e.g., horizontal, vertical), which can affect ease of welding and the strength of the joint.

- Corrosion Resistance: Lap joints and edge joints may trap moisture, leading to corrosion, so additional protective measures may be needed.

Choosing the Right Joint Type

Selecting the appropriate welding joint depends on the project’s requirements, material properties, load conditions and working environment.

- Butt Joints are best for structures requiring smooth finishes and strong, straight connections.

- Lap Joints are ideal for joining thin materials or dissimilar thicknesses.

- Tee Joints work well for right-angle connections in structural load-bearing frameworks.

- Corner Joints are useful for assembling boxes or enclosures.

- Edge Joints are suitable for thin or lightweight materials that are not subjected to high stresses.