Heat treatment is a crucial process in metalworking, designed to alter metal’s physical and mechanical properties. It plays a vital role in industries ranging from automotive to aerospace, offering the ability to improve hardness, strength, ductility, and toughness.

This comprehensive guide will take you through the intricacies of heat treatment, including its purpose, common processes, factors that influence it, heat treatment metals, quality control, defects & solutions and emerging technologies.

1. Purpose of Heat Treatment

The purpose of heat treatment varies based on the desired outcome, whether to increase strength, enhance ductility, relieve internal stresses, or improve machinability. At its core, heat treatment involves raising the metal to a critical temperature, holding it at that temperature for a specified period, and then cooling it.

- Improvement of Mechanical Properties: Metals are treated to enhance their strength, hardness, and toughness to meet the requirements of specific applications.

- Reduction of Internal Stresses: Heat treatment can relieve stresses built up during processes like forging or machining, preventing cracks or warping.

- Increase in Machinability: Some heat treatments make metals softer or more ductile, allowing them to be machined or formed more easily.

2. Heat Treatment Processes

Several methods of heat treatment are used to achieve different mechanical properties. Below are the four most common heat treatment processes:

2.1 Annealing

Annealing is a heat treatment process designed to soften metals, enhance ductility, and relieve internal stresses caused by previous mechanical processes, such as rolling or forging. First, heat the metal to a specific temperature (typically below the metal’s melting point), then cool it slowly in a controlled environment.

This allows the metal’s microstructure to transform into a more stable and refined state, often with larger grains, making it easier to machine or shape. Annealing is commonly used in carbon steels, copper, and aluminum alloys.

2.2 Quenching

Quenching involves rapidly cooling a heated metal to lock in a specific phase of the material, often resulting in increased hardness and strength. The metal is first heated to a high temperature to change its crystalline structure. Then, the metal is rapidly cooled using water, oil, or other quenching media, trapping the material in a harder but more brittle phase, such as martensite in steels.

However, rapid cooling can induce internal stresses and sometimes result in brittleness, which often necessitates further heat treatment processes like tempering.

2.3 Tempering

The purpose of tempering is to reduce the brittleness and internal stresses induced by quenching, while retaining much of the increased hardness. It is often performed after quenching, the metal is reheated to a lower temperature, held for a specific time, and then cooled slowly.

This process is commonly applied to high-carbon and alloy steels to produce tough, wear-resistant components, such as springs, knives, and tools.

2.4 Normalization

Normalization is a heat treatment process commonly applied to ferrous metals to enhance mechanical properties like strength and toughness. In this process, the metal is heated to a temperature above its critical point and then cooled in air. This cooling rate is slower than quenching but faster than annealing, producing a more uniform grain structure with enhanced mechanical properties.

Normalization is typically used in structural components like beams and forgings, as it provides better toughness and ductility than annealing.

3. Key Factors Affecting Heat Treatment

key factors affecting heat treatment include material composition, heating & cooling rate, time at temperature, and atmosphere control.

3.1 Material Composition

The composition of the metal significantly influences how it reacts to heat treatment. For example, carbon content in steel determines the hardness achievable through quenching, while alloying elements like chromium and vanadium impact hardenability and corrosion resistance.

3.2 Heating and Cooling Rates

The rate at which the metal is heated and cooled affects the outcome of heat treatment. A slow cooling rate in annealing can lead to softening, while rapid cooling in quenching creates a harder, more brittle structure. The cooling medium, whether air, oil, or water, also plays a role in controlling these rates.

3.3 Time at Temperature

The duration the metal is held at a specific temperature determines the extent of structural changes. For instance, insufficient time at temperature can result in incomplete transformation during annealing or quenching.

3.4 Atmosphere Control

During heat treatment, the environment in which the process occurs can significantly impact the outcome. In a reactive atmosphere, oxygen and other gases can cause oxidation, scaling, or decarburization. Protective atmospheres, such as inert gases or vacuum conditions, prevent these reactions and help maintain the metal’s integrity and surface quality.

4. Heat Treatment of Specific Metals

Different metals and alloys respond uniquely to heat treatment processes, affecting their strength, hardness, ductility, and overall performance in various applications. The following section highlights how specific metals are treated and their resulting properties.

4.1 Carbon Steel

Carbon steel’s high carbon content makes it particularly responsive to heat treatment. Techniques such as quenching and tempering are frequently employed to enhance hardness and strength, whereas annealing can enhance machinability and ductility. Normalization is also used to refine the grain structure in structural components.

4.2 Alloy Steel

Alloy steels contain additional elements like chromium, molybdenum, and vanadium, which enhance hardenability, corrosion resistance, and wear resistance. Heat treatment processes such as quenching and tempering are tailored to optimize these properties, making alloy steels suitable for demanding applications like aerospace components and cutting tools.

4.3 Aluminum Alloys

Aluminum alloys are typically heat-treated through processes such as solution heat treatment and aging. These treatments improve strength and corrosion resistance by creating precipitates that strengthen the material. However, aluminum cannot be hardened by quenching in the same way as steels, so different techniques are applied to achieve the desired results.

4.4 Titanium Alloys

Heat treatment processes such as annealing, stress relieving, and aging are used to optimize titanium alloys’ excellent strength-to-weight ratio and corrosion resistance properties for aerospace, medical, and chemical processing applications. Careful control of temperature and atmosphere is critical to avoid contamination or oxidation.

4.5 Copper Alloys

Copper alloys, such as brass and bronze, are often annealed to improve their formability and ductility. Unlike ferrous metals, copper alloys do not respond well to quenching, as they become soft rather than hard. Annealing and controlled cooling are preferred to enhance malleability without compromising electrical or thermal conductivity.

5. Quality Control and Testing

Ensuring the quality of heat-treated metals is essential for their performance in critical applications. Several testing methods are used to evaluate hardness, microstructure, and internal defects.

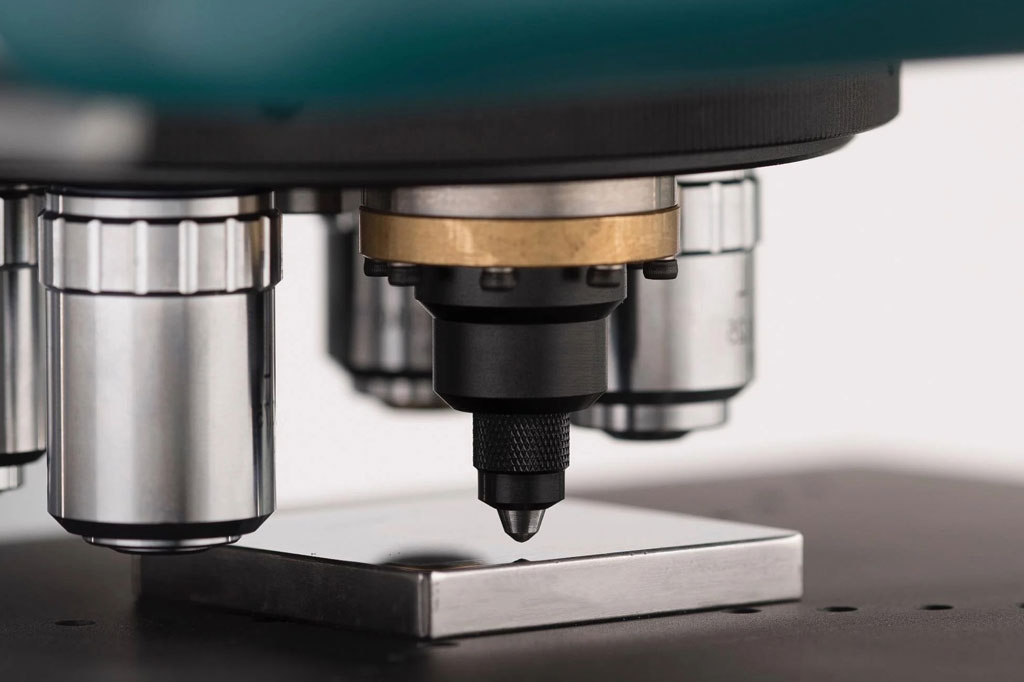

5.1 Hardness Testing Methods

Hardness testing is crucial to assess the success of heat treatment. Common hardness testing methods include the Rockwell, Brinell, and Vickers tests, each of which uses different techniques and loads to assess hardness levels in metals.

- Rockwell: Measures the depth of penetration under a standardized load, ideal for testing metals like steel and aluminum.

- Brinell: Uses a large ball indenter to measure hardness, commonly used for softer metals like copper alloys.

- Vickers: Involves a diamond indenter and is used for precise hardness measurements, suitable for thin materials or complex shapes.

5.2 Microstructure Examination

Microstructure examination involves analyzing the metal’s grain structure, phases, and defects using optical or electron microscopy. This analysis helps verify whether the heat treatment process achieved the desired phase transformations and grain size distribution.

5.3 Non-Destructive Testing Techniques

Non-destructive testing (NDT) techniques, such as ultrasonic and X-ray testing, are used to detect internal flaws like cracks or voids without damaging the component. These methods are crucial for ensuring the integrity of heat-treated metals used in critical applications such as aerospace and automotive parts.

5.4 Metallographic Analysis

Metallographic analysis involves preparing a sample of the heat-treated metal for microscopic examination. By studying the polished and etched surface, engineers can evaluate the effects of heat treatment on the material’s microstructure and identify any defects or irregularities.

6. Common Defects and Solutions

Heat treatment can introduce defects if not properly controlled. Understanding these defects and their causes is essential to implement corrective measures.

6.1 Distortion and Warping

Distortion occurs when different parts of a metal component expand or contract at different rates during heating and cooling. This issue can be mitigated by evenly heating the metal and using proper fixturing during the process.

6.2 Cracking

Cracking can result from rapid cooling during quenching, especially in materials with high carbon content. Preheating and post-heating can help reduce thermal stress and prevent cracking.

6.3 Incomplete Transformation

If the metal is not heated to a sufficient temperature or cooled too slowly, it may undergo incomplete phase transformation. This can lead to lower hardness and strength than expected. Precise temperature and time control can prevent this issue.

7. Emerging Technologies in Heat Treatment

Advances in heat treatment technology are providing more efficient and precise methods for treating metals.

7.1 Induction Heating

Induction heating uses electromagnetic fields to rapidly heat the surface of a metal. This technique is energy-efficient and provides precise control over the heating process, making it ideal for localized heat treatment.

7.2 Vacuum Heat Treatment

Vacuum heat treatment involves heating metals in a vacuum to prevent oxidation or contamination. This technique is particularly beneficial for metals like titanium or high-alloy steels, where a clean surface finish is essential. Vacuum heat treatment also offers precise control over cooling rates.

7.3 Innovations in Quenching Media

New quenching media, including polymer-based solutions and gases, are being developed to provide more controlled cooling rates and reduce the risk of defects like cracking or warping. These innovations enable better customization of heat treatment processes for different metals.