Metal Welding Service

- We are skilled in various welding techniques like MIG, TIG, laster, plasma welding and etc.

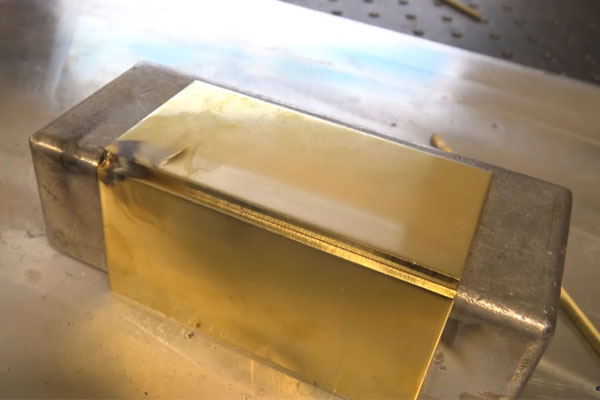

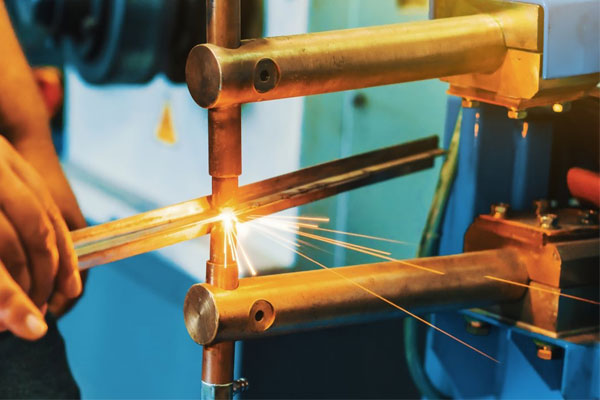

- Allowing us to weld different sheet metals together such as aluminium, steel, stainless steel, cast iron, brass, copper, titanium and more.

- Our advanced processes ensure strong, durable, smooth and aesthetically pleasing welds.

- Wide Range of Welding Capabilities

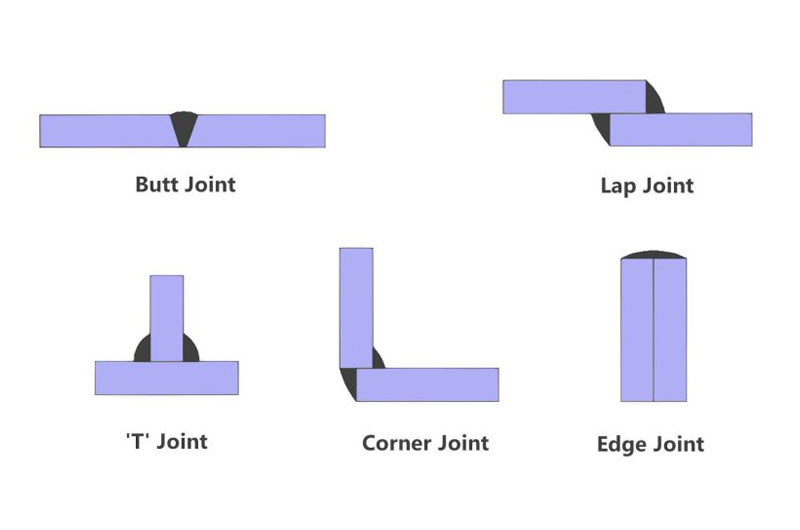

- 5 Basic Welding Joint Types

- Quality Post-Welding Processes

- Defect-free Welds

1. Submit Your Welding Requirements

Share your project requirements, if needed, our engineers can assist in refining designs to meet optimal welding standards.

2. Consultation and Quote

Our team will review your submission, consult with you on the best welding technique (MIG, TIG, Stick, or others), and provide a detailed quote and timeline for completion.

3. Prototyping and Sample Welding

For complex or high-precision projects, we offer prototyping and sample welding services to ensure the final product meets your expectations before mass production.

4. Production and Quality Control

Once you approve, we begin the welding process with strict quality control measures to ensure every joint and weld meets industry standards.

5. Post-Welding Processes

We offer post-weld treatments such as grinding, polishing, or finishing upon request.

How to Work With Us?

Our Welding Capabilities

MIG Welding (GMAW)

- Uses a continuously fed wire electrode and an inert gas (usually argon or a mix) to shield the weld.

- Fast, produces clean welds, suitable for thin to thick materials.

- Suitable for steel, stainless steel, aluminum.

TIG Welding (GTAW)

- Uses a non-consumable tungsten electrode and a filler rod, with an inert gas shield.

- High precision and control, produces high-quality welds.

- Suitable for steel, stainless steel, aluminum, magnesium, and titanium.

Stick Welding (SMAW)

- Uses a consumable electrode coated in flux; the flux vaporizes to protect the weld from oxidation.

- Simple, portable, versatile, no need for external gas.

- Suitable for steel, stainless steel, cast iron.

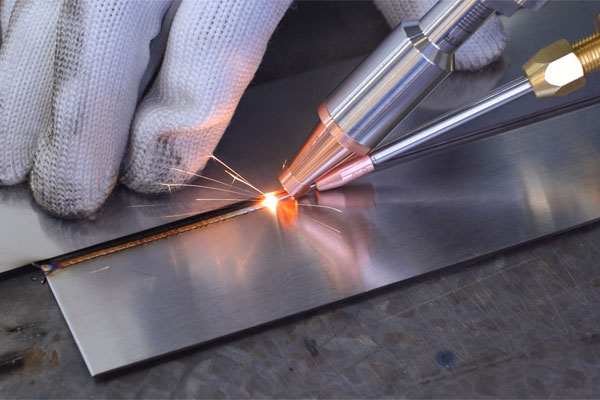

Laser Welding

- Uses a concentrated laser beam to melt the metal surfaces, creating a precise weld.

- Highly accurate, suitable for thin materials, minimal distortion, high speed.

- Suitable for steel, stainless steel, aluminum, titanium, precious metals.

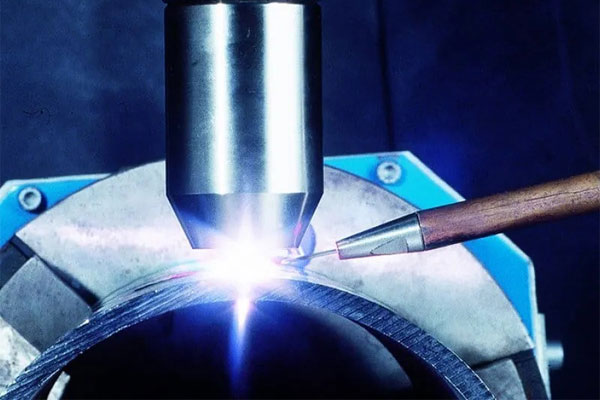

Plasma Welding

- Uses a constricted plasma arc to produce higher temperatures and more focused welds.

- Allows for deep penetration, good for thin materials and complex shapes.

- Suitable fro stainless steel, titanium, copper, brass, nickel alloys.

Gas Welding

- A fuel gas (typically acetylene) is combined with oxygen to create a flame hot enough to melt metals and join them together.

- Portable, versatile, can cut and weld metal, no electricity needed.

- Suitable for steel, copper, aluminum, bronze.

Spot Welding

- Uses electrical resistance to generate heat between two metal surfaces at specific points, fusing them together.

- Fast, efficient, minimal deformation.

- Suitable for thin metals like steel and aluminum.

Seam Welding

- Passing electric current through overlapping metal pieces, heat and press them.

- Strong, leak-proof joints; efficient for long seams.

- Suitable for thin metals, particularly steel and aluminum.

1. Butt Joint

Two metal pieces are aligned in the same plane and welded along their edges, providing strong structural connections, ideal for sheet and plate metal fabrication.

2. Lap Joint

Overlapping two metal pieces and welding along the edges, commonly used for joining thinner materials, ensuring durability and strength in assemblies.

3. Tee Joint

One metal piece is welded perpendicularly to another, forming a "T" shape, often used in structural frameworks for added strength and support.

4. Corner Joint

Two metal pieces are welded at a right angle to form an exterior corner, used in box or frame constructions, offering strong and clean finishes.

5. Edge Joint

The edges of two adjacent metal pieces are welded together, suitable for joining thin metal sheets, often used in light fabrication projects.

Basic Metal Welding Joint Types

Post-Welding Processes

Surface Finish

Heat Treatment

Strengthens welded metal’s properties by applying controlled heating and cooling processes, enhancing durability and structural performance.

Non-Destructive Testing (NDT)

Welding Defects & Solutions

Porosity

- Small gas pockets trapped in the weld bead.

- Caused by contaminants on the base metal, incorrect shielding gas or flow rate.

- Ensure thorough cleaning of the base material before welding. Use appropriate shielding gases and ensure proper flow rates. Control cooling rates.

Undercutting

- A groove formed at the edge of weld bead.

- Caused by excessive welding current, improper speed or incorrect electrode angle.

- Adjust the welding parameters (voltage, amperage, travel speed), use proper electrode angle, and use weaving techniques if necessary to fill the groove.

Cracks

- Fractures in the weld or heat-affected zone.

- Caused by high stress concentrations, inadequate preheating or cooling.

- Use proper preheating techniques before welding. Control the cooling rate after welding (slow cooling or post-weld heat treatment). Ensure appropriate joint design.

Distortion

- Warping of the welded components.

- Caused by uneven heat distribution during welding. Large temperature gradients.

- Use balanced welding techniques to minimize heat concentration. Employ fixtures to hold workpiece firmly. Consider using multi-pass welding to distribute heat more evenly.

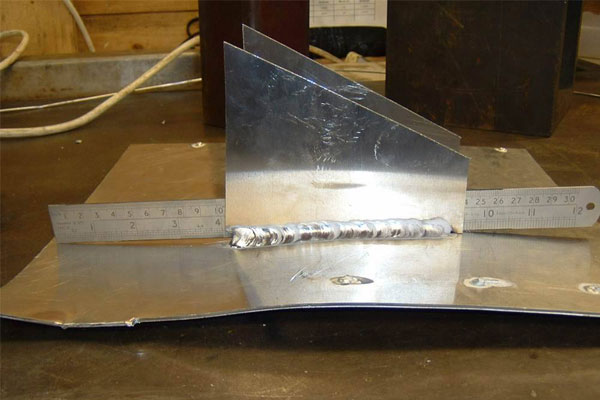

Our Welding Projects