Sheet metal fabrication is an essential process in manufacturing, enabling the creation of a wide array of products across various industries. From automotive parts to household appliances, the applications are endless.

This article delves into the eight basic sheet metal fabrication techniques that form the foundation of this vital industry.

Cutting

The initial phase in most sheet metal fabrication processes is the metal cutting, which entails shaping and sizing the metal sheets as needed. Sophisticated cutting methods like laser cutting, plasma cutting, and waterjet cutting allow for highly accurate and detailed cuts.

These methods are crucial for achieving detailed designs and reducing material waste.

- Laser Cutting: Employs a high-powered laser beam to achieve extremely precise cuts, making it perfect for intricate and complex shapes.

- Plasma Cutting: Involves a high-velocity jet of ionized gas to cut through thicker metal sheets efficiently and cost-effectively, suitable for heavy-duty applications.

- Waterjet Cutting: This method of cutting metal without producing heat and maintaining the material’s characteristics uses a high-pressure spray of water combined with abrasive particles.

Sheet Metal Cutting Methods Comparison

Cutting Method | Laser Cutting | Plasma Cutting | Waterjet Cutting |

Precision | High | Moderate | Very High |

Compatible Metals | Steel, Aluminum, Brass, Copper | Steel, Aluminum, Stainless Steel | Steel, Aluminum, Titanium, Copper, Brass, Alloys |

Thickness Capability | Up to 25mm | Up to 50mm | Up to 200mm |

Applications | Fine cutting, Intricate designs, High precision parts | General fabrication, Industrial applications | Thick materials, Mixed materials, Sensitive materials |

Heat Affected Zone | Small | Large | None |

Cutting Speed | High | Very High | Moderate |

Operating Costs | High | Moderate | High |

Environmental Impact | Moderate | High | Low |

Bending

Bending transforms flat sheet metal into angular shapes by applying force along a straight axis. This can be achieved using press brakes, which bend the metal to the desired angle or roll bending, which creates cylindrical and curved shapes.

Custom metal bending is fundamental for creating components with varied angles and profiles.

- Press Brakes: Machines that use a die and punch to bend the metal at precise angles. Ideal for producing precise bends and folds.

- Roll Bending: Uses multiple rollers to shape the sheet metal into curved forms or cylindrical shapes. Ideal for making rounded shapes and components.

Types of Sheet Metal Bending:

- V-Bending: Common; creates various angles with a V-shaped die.

- Air Bending: Versatile; a range of angles by controlling punch depth.

- Bottoming (Coining): Precise; metal fully pressed into the die.

- U-Bending: Creates U-shaped profiles.

- Offset Bending: Produces Z-shaped bends.

- Roll Bending: Large radius bends or cylindrical shapes.

- Wiping (Edge Bending): Bends along the edge; creates flanges and hems.

- Rotary Bending: Reduces surface marking; good for cosmetic finishes.

Angles in Sheet Metal Bending:

- Acute Angle Bend: Less than 90 degrees; used for sharp bends.

- Right Angle Bend: Exactly 90 degrees; common in structural parts.

- Obtuse Angle Bend: Greater than 90 but less than 180 degrees; used for wider angles.

- Hem Bend: Edge folded back on itself; adds strength and safety.

- Curl Bend: Edge curved into a circular profile; for safe handling and aesthetics.

- Seam Bend: Multiple bends for joining parts; used in ductwork and assemblies.

Stamping

Stamping is the process of forming precise forms and patterns out of sheet metal by pressing it into a die. This technique, which involves steps like blanking, embossing, and flanging, is very effective for mass production.

Metal stamping service is widely used in automotive and appliance manufacturing for producing consistent and complex parts.

- Blanking: Cutting the sheet metal into predefined shapes or blanks.

- Embossing: Using raised or recessed patterns for aesthetic or practical effects on a metal surface.

- Flanging: Bending the edges of the sheet metal to form flanges, adding strength and allowing for assembly with other components.

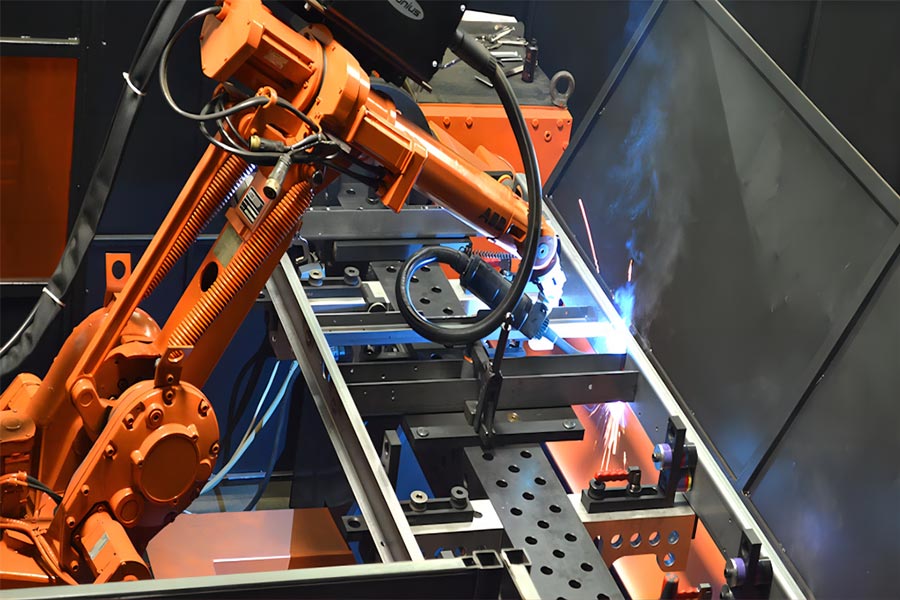

Welding

Welding is a key technology for joining metal parts together. Common metal welding services include the following three. These methods provide a strong, long-lasting bond, which is essential to the structural and functional integrity of metal components.

- MIG Welding: This method of joining metals involves using an inert gas and a continuous wire feed. Well-known for its quickness and usability.

- TIG Welding: Employs a tungsten electrode and inert gas, offering precise control for high-quality welds.

- Spot Welding: Involves applying pressure and an electric current to join overlapping metal sheets at specific points, commonly used in automotive manufacturing.

Sheet Metal Welding Types Comparison

Welding Types | MIG Welding | TIG Welding | Spot Welding |

Process | Arc welding | Arc welding | Resistance welding |

Welding Speed | Fast | Slow | Very fast |

Material Thickness | Medium to thick | Thin to medium | Thin |

Precision | Moderate | High | Low |

Typical Applications | Automotive repair, construction | Aerospace, automotive, art | Automotive manufacturing, electronics |

Punching

Punching creates holes or cutouts in sheet metal by forcing a punch through the material into a die. Custom metal punching is efficient for producing multiple holes or shapes quickly and accurately, making it ideal for applications like creating perforated metal panels and brackets.

- Single Punch: Creates individual holes or shapes one at a time.

- Turret Punch: Uses a rotating turret with multiple tools to perform various punching operations in a single setup, increasing efficiency and speed.

Shearing

Shearing cuts large sheets of metal into smaller, more manageable pieces by applying a cutting force perpendicular to the sheet. This process is ideal for making straight cuts and is commonly used for trimming or resizing sheet metal to the required dimensions.

- Guillotine Shear: Uses a straight blade that descends vertically to cut the metal sheet in a straight line.

- Alligator Shear: Features a hinged jaw that cuts the metal in a scissor-like motion, suitable for cutting long lengths of metal.

Forming

Forming shapes sheet metal without removing any material. Techniques such as hydroforming and deep drawing allow for the creation of complex, deep, and hollow shapes. Deep drawing involves pulling the metal into a die, while hydroforming uses high-pressure hydraulic fluid to force the metal into a mold.

- Hydroforming: Utilizes hydraulic pressure to form the metal into intricate shapes with uniform thickness.

- Deep Drawing: Involves pulling a sheet metal blank into a die to form deep, hollow shapes, commonly used for making cans and containers.

Finishing

Finishing methods improve the functionality and look of sheet metal components. Processes such as polishing, painting, coating, and anodizing are used to improve surface smoothness, corrosion resistance, and aesthetic appeal. Assuring that the product satisfies the required specifications and quality standards is the last phase, finishing.

- Polishing: Smoothing the surface to achieve a shiny, reflective finish.

- Painting/Coating: Applying protective coatings or paint to prevent corrosion and improve aesthetics.

- Anodizing: An electrochemical procedure used mostly on aluminum that improves surface hardness and resistance to corrosion.

Conclusion

Understanding these eight basic sheet metal fabrication techniques is crucial for anyone in manufacturing. Each method has unique benefits and suits different applications, from intricate designs to secure component joining. Gaining proficiency in these methods guarantees productive, economical, and high-quality production operations.