One-stop Solution For Your Precision Parts

- We provide customers with comprehensive, high-quality, and economical production solutions, covering the entire industry chain from raw material control, production, testing, packaging, logistics, after-sales service, etc.

- Multiple machining processing techniques

- Low Tolerance

- Surface treatment

- Rapid prototyping

- Low MOQ

- Customization support

Our Service

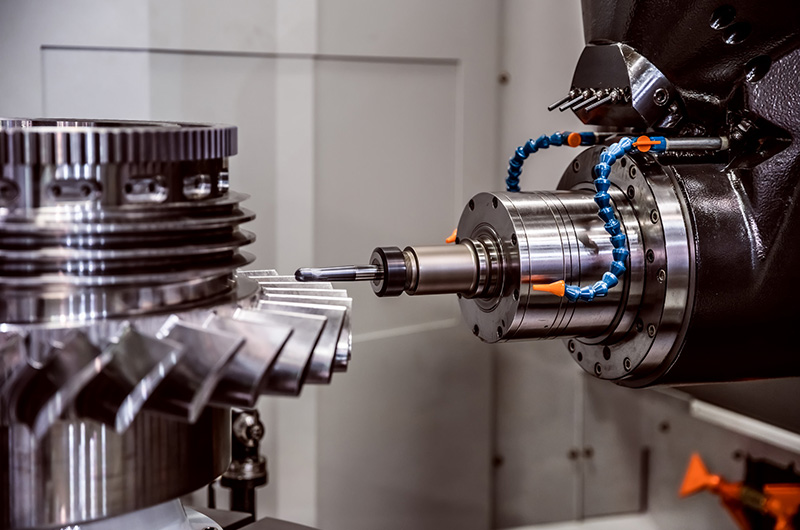

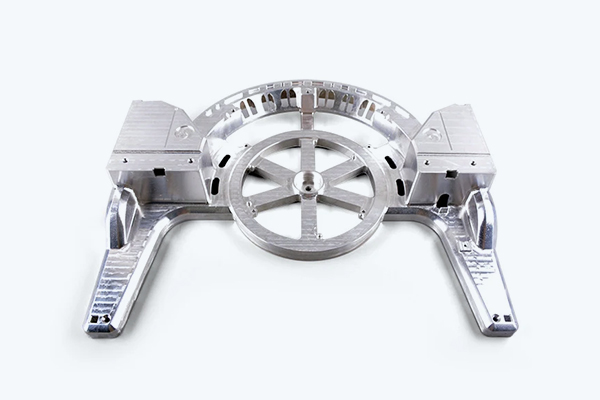

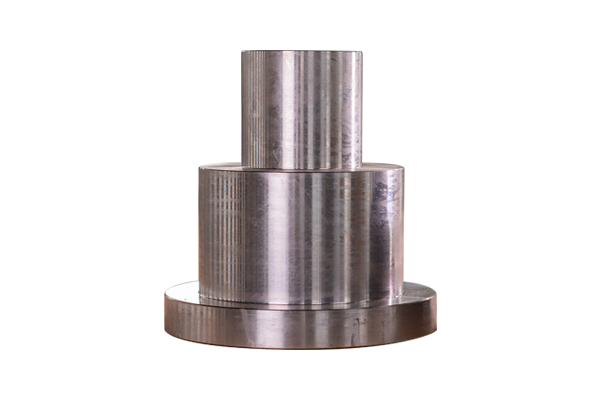

CNC Machining

Involves computer-controlled machines to precisely cut and shape materials into desired components, ensuring high accuracy and repeatability for complex designs.

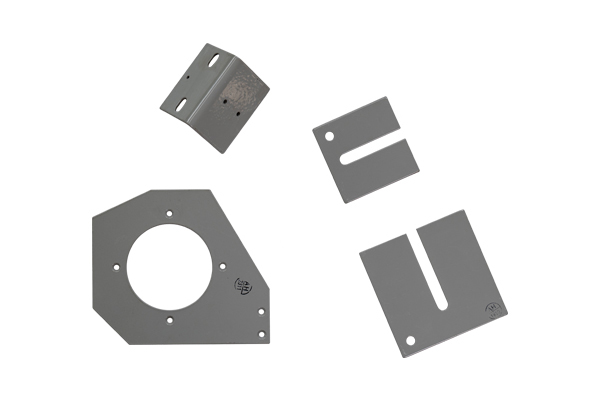

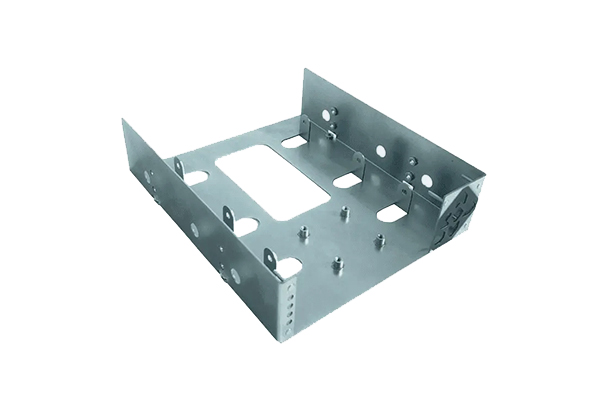

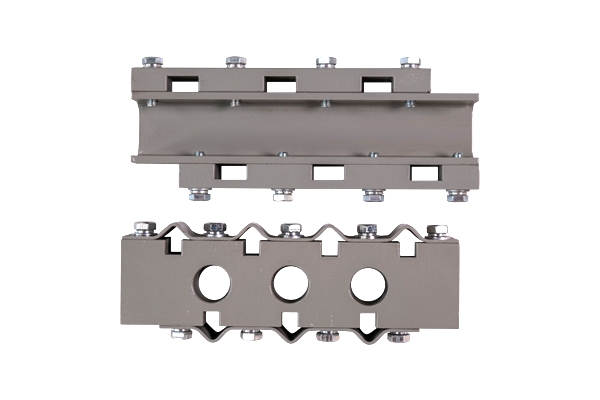

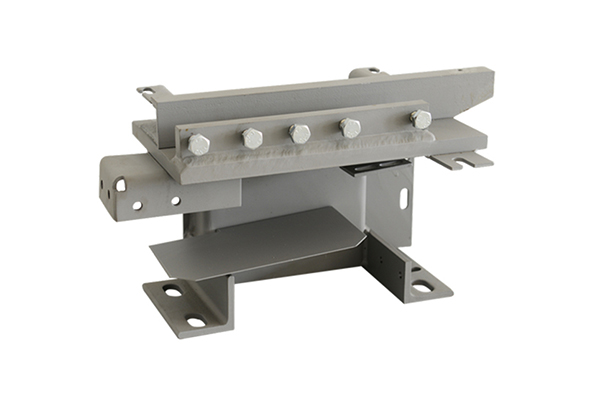

Sheet Metal Fabrication

Includes cutting, bending, and assembling metal sheets into functional parts, used in various industries for enclosures, brackets, and structural components.

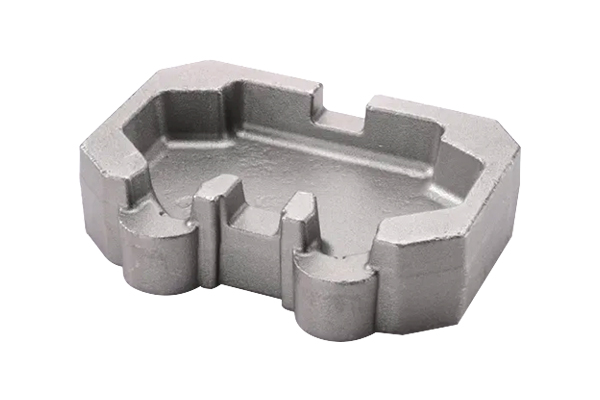

Forging

Shaping metal using compressive forces, typically by hammering or pressing, to create high-strength components with refined grain structures.

Welding

Fusing two or more metal pieces by melting them and adding a filler, creating a strong, continuous bond as the materials cool, resulting in robust connections.

Surface Finishes

Enhance the appearance, durability, and performance of parts through processes like painting, plating, and anodizing, providing protection and aesthetic appeal.

Industries We Service

We provide comprehensive manufacturing and processing solutions tailored to diverse industries’ requirements. Let’s explore some of the sectors where our services are applied.

- Automotive

- Energy

- Aerospace

- Elevator Equipment

- Military and Defense

- Medical Equipment

- Mining machinery

- Hoisting Machinery

- Industrial Machinery and Equipment

- Electrical

- Robotics

- Port Machinery

- Electronics

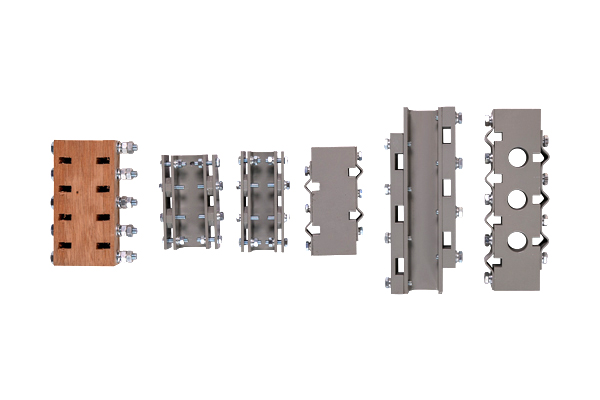

Our Projects

About Us

- After 2017, according to the market development situation, we decided to enter the precision metal & plastic components fabrication. We have successfully serviced many industries, from construction building, automotive, medical, aerospace, port machinery, engineering machinery, and other industries.

- To date, we have accumulated rich experience in CNC machining, sheet metal fabrication, welding, metal cutting, die casting, heat treatment, surface treatment, and plastic products.

- We are willing to provide products and services with good quality, favorable prices and timely delivery to major customers in the industry. We warmly welcome foreign colleagues to visit our company and discuss cooperation!

Why Choose Us

Cost-effective

With advanced machines, expert team, and high-quality raw materials at competitive prices, we had shorten the prototyping time and improved the yield rate of mass production.

High-Precision

Precision is at the core of our operations. We guarantee that each piece is crafted to exact specifications, with a tolerance from ±0.005" (±0.13 mm) to ±0.0005" (±0.0127 mm).

Quick Prototyping

From simple to highly complex designs, our rapid prototyping can be controlled within 1~7 days, allowing our clients to test and refine their designs with minimal delay.

Quality Assurance

We have certified to ISO 9001:2015, from initial production to final delivery, we maintain strict quality control to ensure compliance with customer requirements.

Start Your Parts & Components Now

From Concept to Production: Send Enquiry -> Communication -> Prototyping -> Mass Production

Our Clients Around the World

Latest News & Blog

Sterilization boxes are essential in healthcare, laboratory, pharmaceutical, and industrial settings, requiring precise, durable design to protect contents during sterilization, […]

Sterilization boxes are vital in medical, laboratory, pharmaceutical, and industrial settings, protecting instruments during sterilization, storage, and transport while meeting […]

Sterilization boxes are essential in medical, dental, laboratory, and pharmaceutical settings, protecting instruments through sterilization, storage, and transport. This article […]